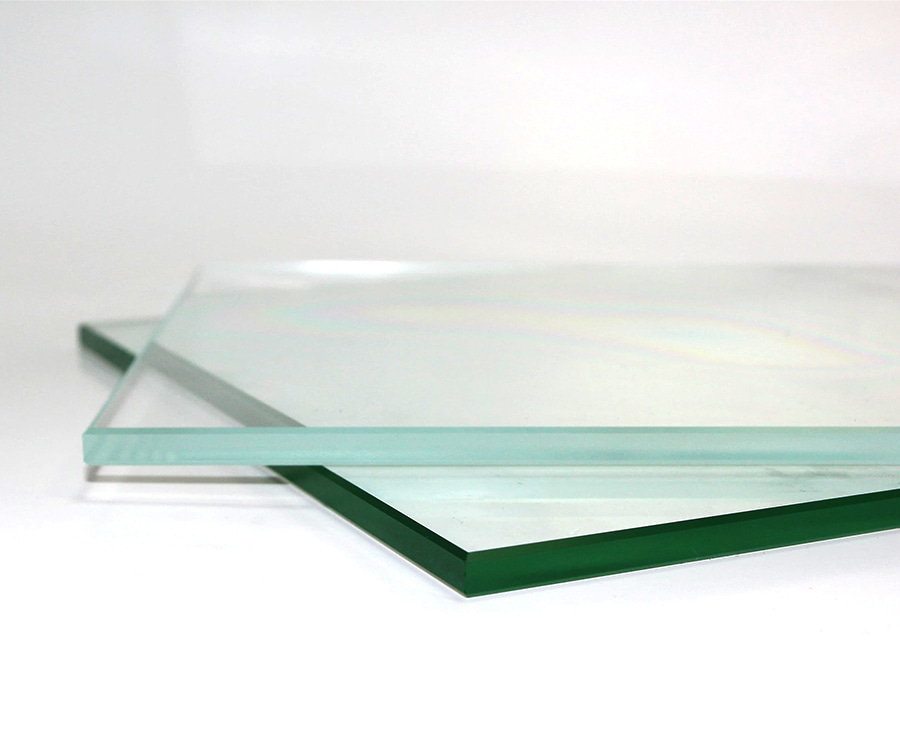

Home appliance display glass usually uses ultra-white glass as the base material, and its core advantage lies in its extremely high light transmittance and extremely low color deviation. Ordinary glass contains iron elements, which will show a slight green tone, affecting the penetration of light and causing the color of the screen display to deviate. Ultra-white glass has an extremely low iron content and a light transmittance of more than 91%, so that there is almost no color deviation when light passes through the glass, thereby ensuring that the color of the display is true and natural, closer to the original image effect.

The flatness of the glass is crucial to the display effect. If there are bumps or deformations on the surface, it will cause uneven refraction of light and affect the accurate reproduction of colors. Home appliance display glass uses high-precision CNC processing technology to ensure that the flatness error of the glass surface is controlled within ≤0.1mm, effectively reducing the scattering and distortion of light, making the screen display clearer and the color distribution more uniform. This process is particularly suitable for high-end home appliances, such as OLED TVs, smart refrigerator touch panels, etc., to ensure the best visual experience.

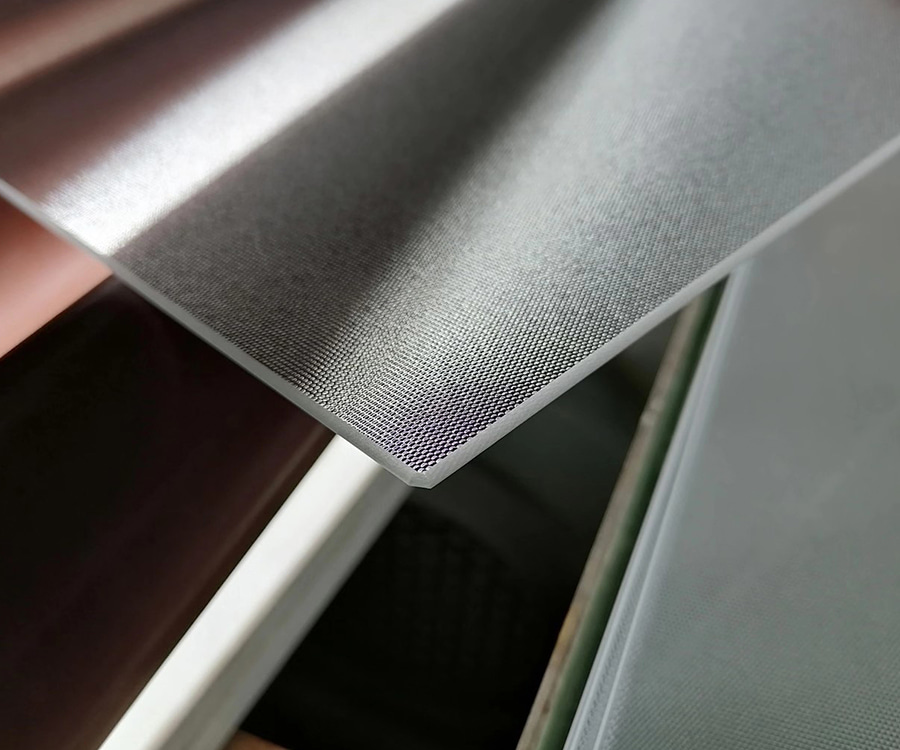

Ordinary glass has a high surface reflectivity, which is easy to form glare in strong light environment, interfere with screen display, and cause color contrast to decrease. Home appliance display glass can use AR coating technology to reduce the reflectivity to less than 1%, greatly improving the visibility and color vividness of the screen. In addition, AG treatment can scatter ambient light through a fine frosted surface to reduce glare interference. It is suitable for scenes such as shopping mall display cabinets and outdoor smart devices to ensure that the screen can still present accurate colors under different lighting conditions.

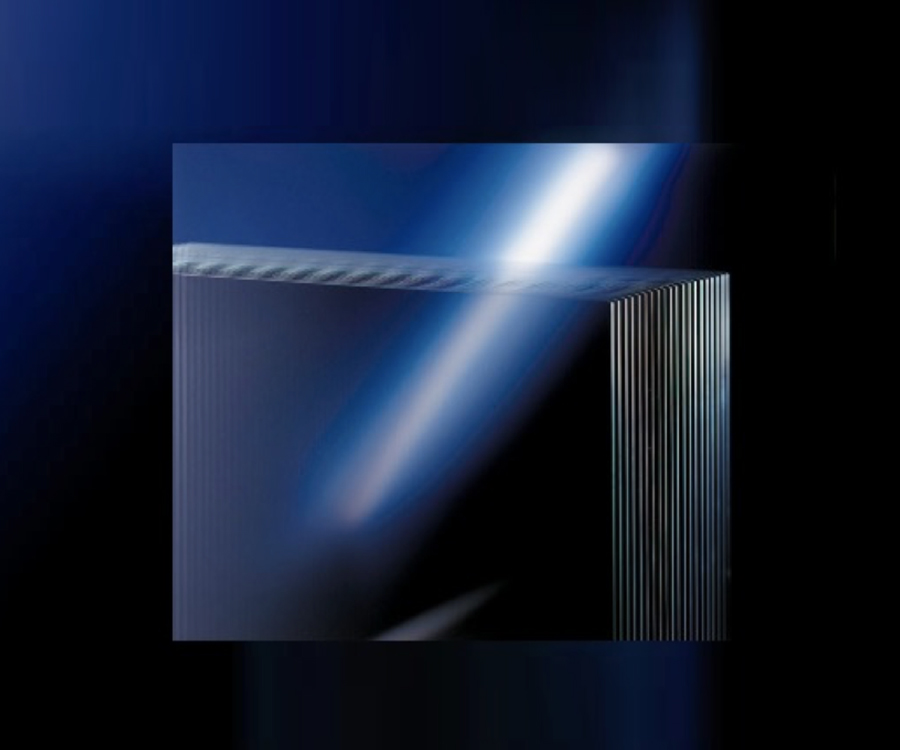

Unreinforced glass may have problems with uneven internal stress. When subjected to temperature changes or mechanical pressure, it may cause slight deformation, which in turn affects the refraction path of light and causes color deviation. Home appliance display glass uses chemical tempering or thermal tempering processes to enhance the mechanical strength and thermal stability of the glass, eliminate internal stress, and enable the glass to maintain stable optical properties during long-term use, avoiding display color distortion caused by stress deformation.

Appliance display glass uses a series of optimization measures such as ultra-clear glass substrate, high-flatness CNC processing, AR/AG coating, tempered reinforcement, precision printing process and optical bonding technology to ensure that the color displayed on the screen is highly restored and the visual effect is clear, bright and stable. These technologies are not only suitable for high-end home appliances, such as smart TVs, smart refrigerators, high-end ovens, etc., but also meet the application scenarios with strict display quality requirements such as commercial display equipment and smart home panels.