Solar glass, as a core component of photovoltaic modules, directly affects the efficiency and lifespan of solar panels through its manufacturing process. This special glass, with its high light transmittance and excellent physicochemical properties, is a key medium for converting sunlight into electrical energy.

Content

Raw Material Preparation: Ultra-Clear Glass is the Foundation

The first step in manufacturing solar glass is selecting high-quality raw materials, the core of which lies in producing "ultra-clear glass."

- Raw Material Selection: This mainly includes quartz sand, soda ash, and dolomite. To ensure the high light transmittance of photovoltaic glass, these raw materials must undergo rigorous screening, especially the quartz sand, which requires extremely high purity to ensure a very low iron content in the final glass (typically below 0.015%).

- Fine Processing: The raw materials undergo weighing, mixing, and grinding processes. Typically, the raw materials need to be ground into extremely fine powder and thoroughly mixed to ensure uniform composition during melting.

Melting and Forming: High Temperatures Forge Quality

After raw material preparation, the high-temperature melting and forming stage begins, a crucial step determining the quality of solar glass.

- High-Temperature Melting: The mixed raw materials are fed into a melting furnace and melted into a homogeneous molten glass at temperatures reaching approximately 1500℃. This process requires strict temperature and time control to remove air bubbles and impurities from the molten glass.

- Forming Process: Currently, there are two main photovoltaic glass forming processes on the market:

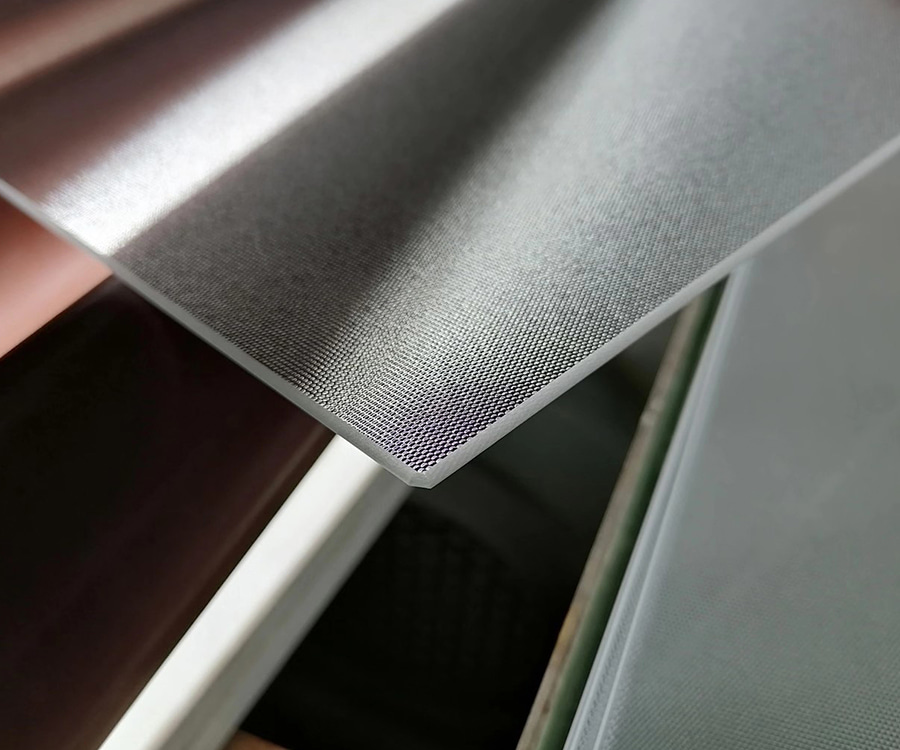

- Ultra-clear rolled glass: Primarily used in crystalline silicon solar cell modules. The molten glass is extruded and formed using rollers, typically with regular embossed patterns on the surface to reduce light reflection and increase light capture. This process produces photovoltaic glass with higher light transmittance and is the mainstream technology in the market.

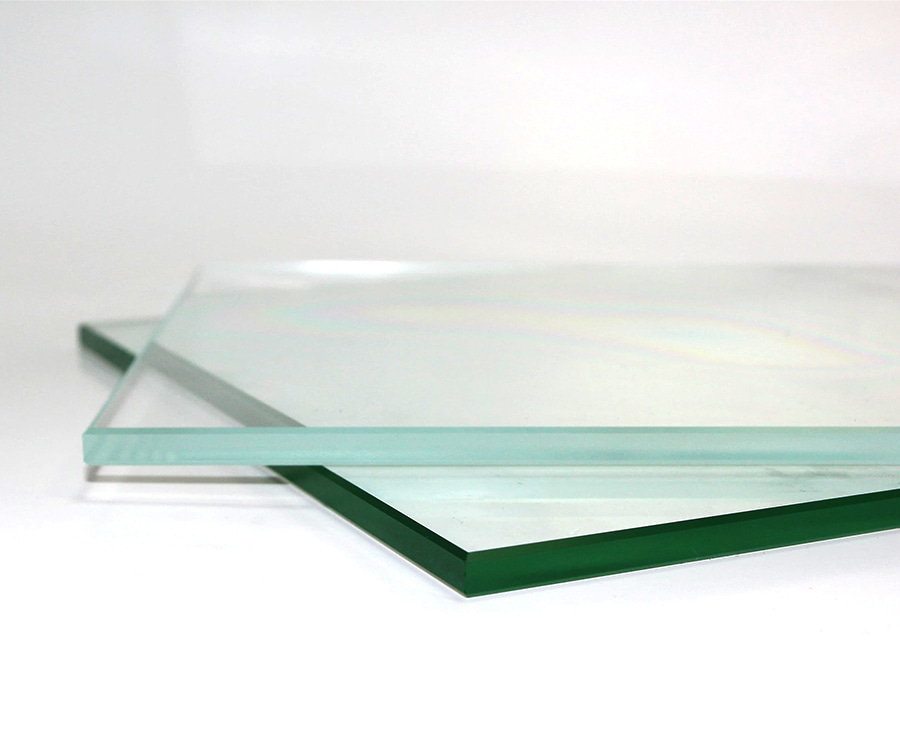

- Ultra-clear float glass: More commonly used in thin-film solar cell modules. The molten glass floats on the surface of molten tin, relying on surface tension to form a smooth glass ribbon with a high surface finish.

- Ultra-clear rolled glass: Primarily used in crystalline silicon solar cell modules. The molten glass is extruded and formed using rollers, typically with regular embossed patterns on the surface to reduce light reflection and increase light capture. This process produces photovoltaic glass with higher light transmittance and is the mainstream technology in the market.

Post-processing: Further Performance Enhancement

After the raw glass is formed, it undergoes a series of post-processing steps to achieve the physical and chemical properties required for solar glass.

- Tempering (Increased Strength): To ensure the impact resistance of solar glass during extreme weather and installation, the raw glass undergoes tempering (heat tempering or semi-tempering). This gives the glass higher mechanical strength and thermal stability, making it less prone to breakage.

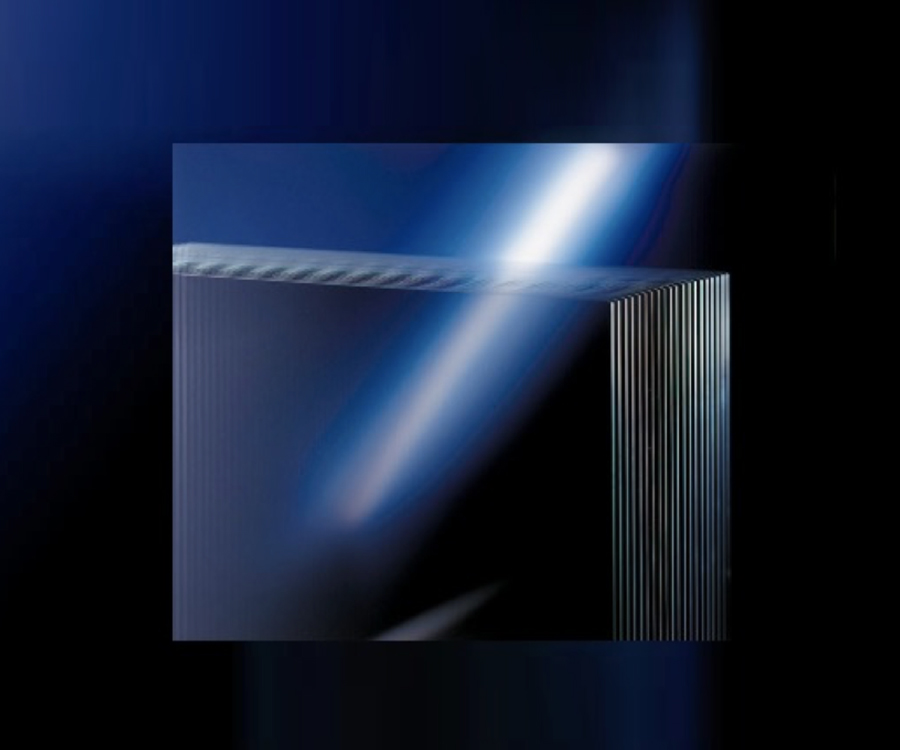

- Coating Technology (Reduces Reflection): To further improve the light transmittance of photovoltaic glass and reduce light loss due to reflection on the glass surface, a coating is applied to form an anti-reflective coating. This thin film can increase the light transmittance of the glass to over 91.5%.

- Cutting and Trimming: Finally, the processed solar glass undergoes high-precision cutting and edge trimming according to the required dimensions of the photovoltaic modules, ensuring compliance with encapsulation requirements.

The manufacturing of solar glass is a complex, multidisciplinary, and highly precise engineering process. From selecting raw materials to high-temperature melting, and then to precise tempering and coating processes, every step aims to improve the power generation efficiency and long-term reliability of photovoltaic modules. With the continuous growth of global demand for renewable energy, photovoltaic glass, as a key material, will continue to innovate in its manufacturing technology, contributing to the popularization of green energy.