The lightness of ultra-thin LCD panel substrate glass, as one of its core competitive advantages, is achieved through a series of carefully designed and optimized manufacturing processes and material selection. Electronic-grade ultra-thin glass materials themselves have low density and excellent mechanical properties, such as high strength and high toughness. This material selection not only ensures the lightness of the product, but also ensures its stability and durability in various application environments.

Manufacturing process and technology

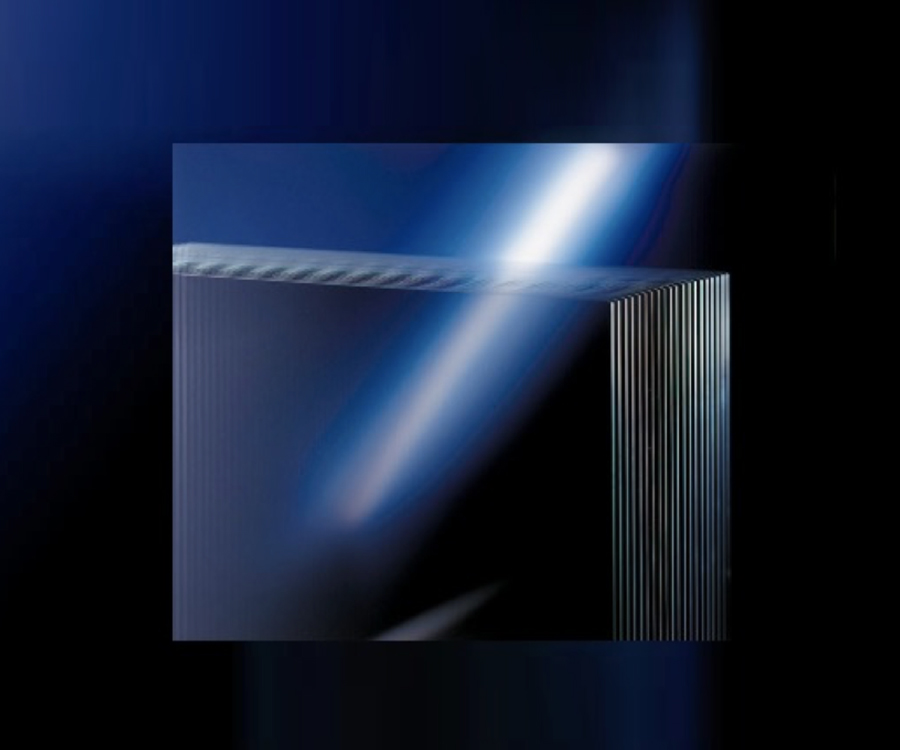

The thickness of the glass can be precisely controlled by combining chemical etching and physical polishing while maintaining the flatness and finish of its surface. This process not only improves the aesthetics of the product, but also further reduces the weight. Such as the float method, overflow melting method, etc., these technologies can produce ultra-thin glass substrates with uniform thickness and excellent surface quality. Among them, the float method uses the natural flow and solidification process of molten glass on the liquid tin bed to achieve precise control of the glass thickness; while the overflow melting method further improves the quality and performance of the product by optimizing the flow and solidification conditions of the molten glass.

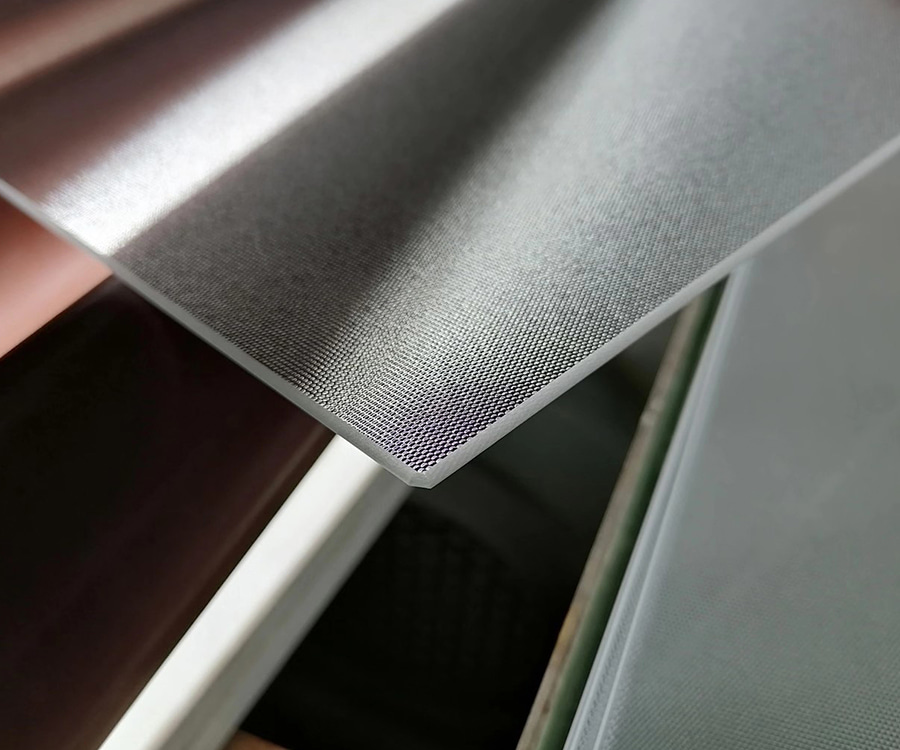

During the manufacturing process, the glass is precisely edged and cleaned multiple times to ensure that its edges are smooth and the surface is free of stains and impurities. These processing steps not only improve the aesthetics of the product, but also avoid performance degradation caused by sharp edges or surface contamination. Through tempering, the strength and impact resistance of the glass can be enhanced while maintaining its lightness. This treatment method allows ultra-thin LCD panel substrate glass to have better durability and reliability while maintaining its lightness.

By optimizing the composition and process technology of the glass, its density and thermal expansion coefficient can be reduced. This not only further reduces the weight of the product, but also reduces the dimensional changes caused by temperature changes, thereby improving the stability and reliability of the product. Ultra-thin LCD panel substrate glass needs to have good light transmittance and clarity to ensure the quality and effect of the LCD display. Therefore, the optical performance parameters such as light transmittance and refractive index of the glass need to be strictly controlled during the manufacturing process.

The lightness of ultra-thin LCD panel substrate glass is achieved by selecting high-quality electronic-grade ultra-thin glass materials, adopting advanced thinning processes and process technologies, and optimizing physical properties and optical properties. These measures not only improve the lightness and aesthetics of the product, but also ensure its stability and durability in various application environments.