Home appliance panel glass often uses screen printing or UV digital printing technology to print patterns, LOGO or textures on the surface. This process can achieve high-precision color reproduction, support a variety of effects such as imitation metal, wood grain, marble, etc., and meet the aesthetic needs of different products. The printed ink has excellent wear resistance and scratch resistance, and is not easy to fade after long-term use. It is suitable for control panels or decorative areas of home appliances such as refrigerators, washing machines, and ovens. In addition, multi-color printing can also be combined with touch functions to achieve intuitive interactive interface design on smart home appliances.

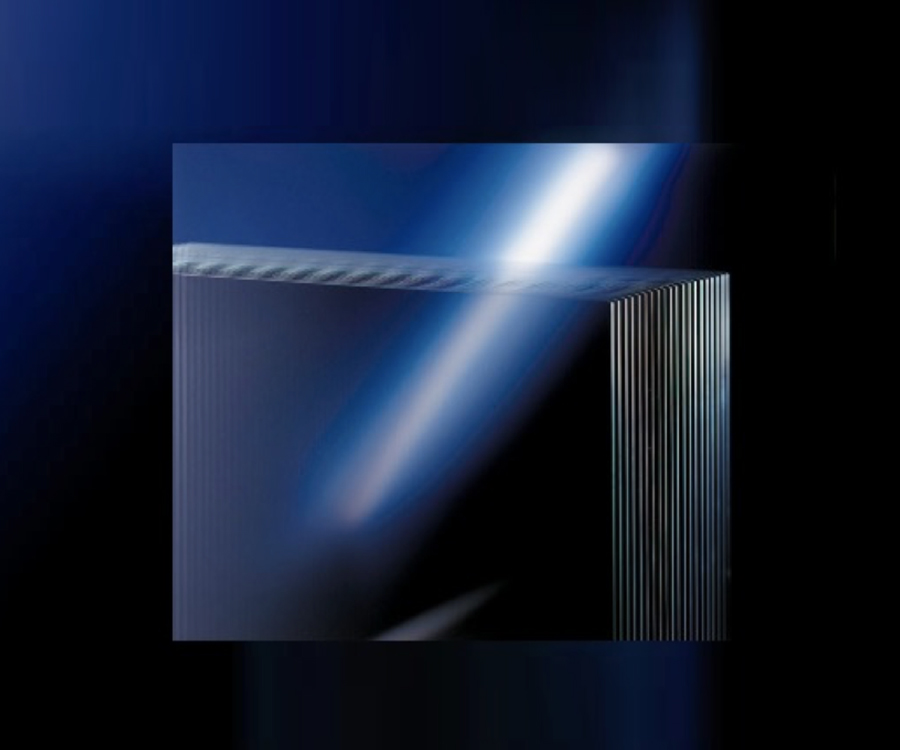

AG frosted treatment forms a subtle concave and convex structure on the glass surface through chemical etching or spraying technology, effectively reducing light reflection and glare interference. This matte effect not only improves visibility in strong light environments, but also brings a delicate touch, and is anti-fingerprint and easy to clean. AG glass is widely used in display screens or operation panels of equipment such as TVs, microwave ovens, and air conditioners. It is particularly suitable for scenes with complex light such as kitchens and living rooms, ensuring that users can clearly read the screen content at any angle.

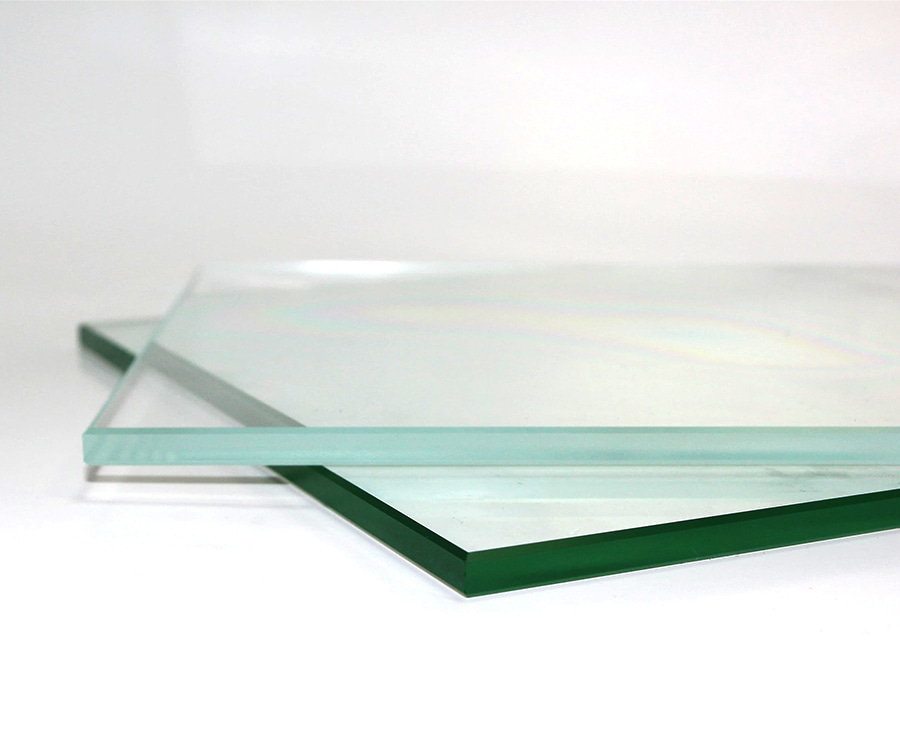

AR coating technology significantly reduces light reflection by depositing multiple layers of optical film on the glass surface, and the light transmittance can be increased to more than 95%. This treatment makes the screen display clearer and brighter, reducing ambient light interference, similar to the visual effect of high-end smartphones or TVs. AR coating can also be combined with AG frosting process, which has both anti-glare and high light transmittance characteristics. It is suitable for transparent display screens of smart refrigerators, oven observation windows and other areas that require high clarity, providing users with a more comfortable viewing experience.

IMD and IML processes embed pre-printed films into the glass layer and form them at high temperature and high pressure to achieve three-dimensional patterns or dynamic backlight effects. This technology not only makes the pattern more durable and corrosion-resistant, but also can design 3D touch buttons or translucent logos to enhance the product's sense of technology and interactivity. Combined with tempered glass, it has higher strength and is suitable for high-end range hoods, dishwashers and other home appliance panels that require frequent operation and high durability requirements.

Through PVD or electroplating processes, metal coatings such as gold, silver or black can be formed on the glass surface, presenting a luxurious effect of mirror or brushed metal. This treatment not only enhances the visual grade of the product, but also has corrosion resistance and anti-oxidation properties, suitable for use in humid environments such as kitchens. Electroplated glass is commonly found in high-end refrigerator door panels, coffee machine panels and other products, adding a sense of modernity and quality to home appliances.

Laser technology can accurately engrave text, patterns or functional light-transmitting holes on the glass surface to achieve permanent marking without the use of ink. This non-contact processing method has extremely high precision and is suitable for making light-transmitting buttons, decorative textures or brand logos. The laser-engraved patterns are wear-resistant and not easy to fall off. They are widely used in parts that need to maintain clear markings for a long time, such as the water level scale of washing machines and the indicator light area of air purifiers.

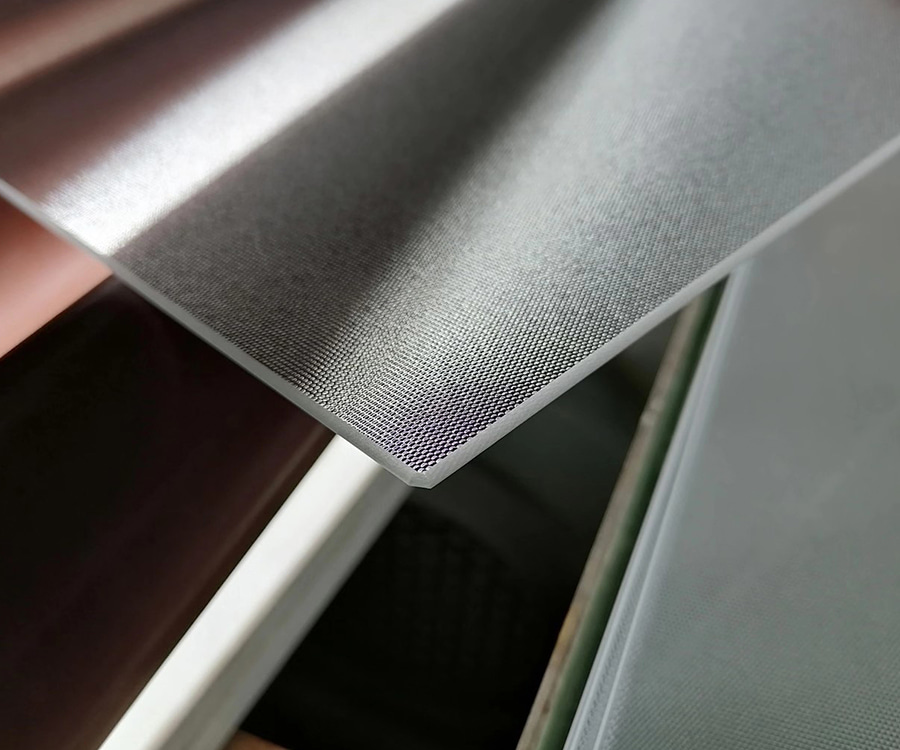

PDLC dimming glass uses voltage to control the transparency or atomization state of the glass by sandwiching a dimming film between two layers of glass. This technology combines privacy protection and dynamic display functions, and is full of technology, but it requires circuit design and is relatively expensive. Smart dimming glass is suitable for scenes such as hidden displays of high-end refrigerators and smart bathroom mirrors, providing users with a more flexible and modern use experience.