With renewable energy gaining increasing attention, solar glass, as a new material in the photovoltaic field, is gradually gaining public attention. Whether used in photovoltaic module backsheets or integrated into building facades, the durability and long-term performance of solar glass are of paramount concern to users and the industry.

Content

Core Component Lifespan Guarantee: 25 Years or Even Longer

For standard crystalline silicon photovoltaic modules, their service life is primarily determined by the degradation rate of the core materials—the photovoltaic glass (including the cover glass and backsheet glass)—and the solar cells. Manufacturers typically offer a 25-year power output guarantee for high-quality solar glass photovoltaic modules. This means that under normal operating and maintenance conditions, the module will still maintain at least 80% of its initial rated power after 25 years.

In fact, many studies and early installation cases indicate that the actual service life of high-quality solar glass photovoltaic modules can exceed 30 years.

Key Factors Affecting Solar Glass Lifespan

Material Quality and Weather Resistance

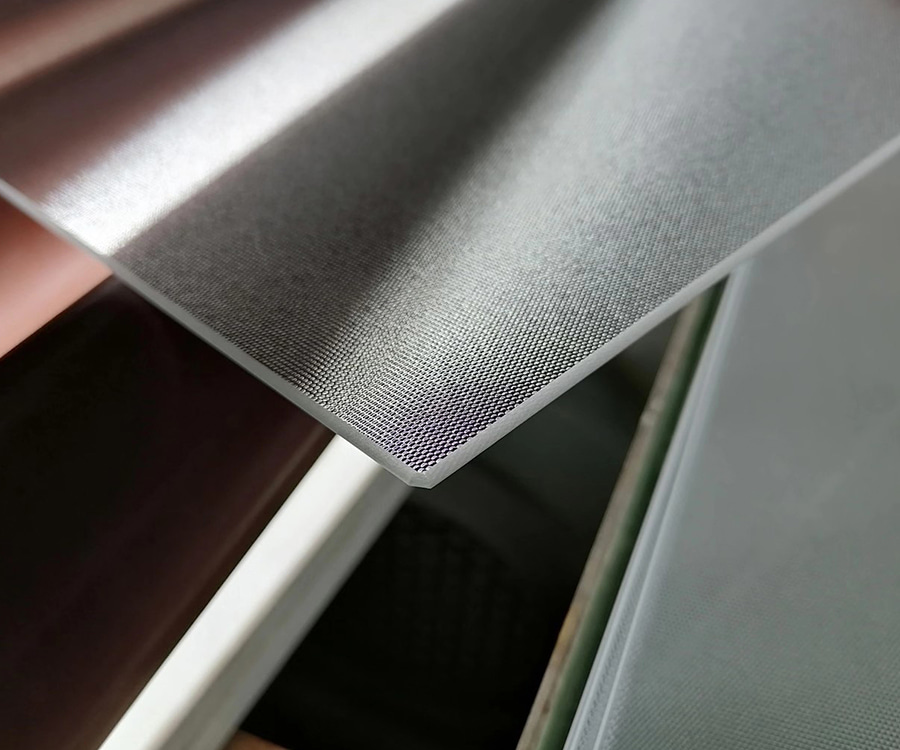

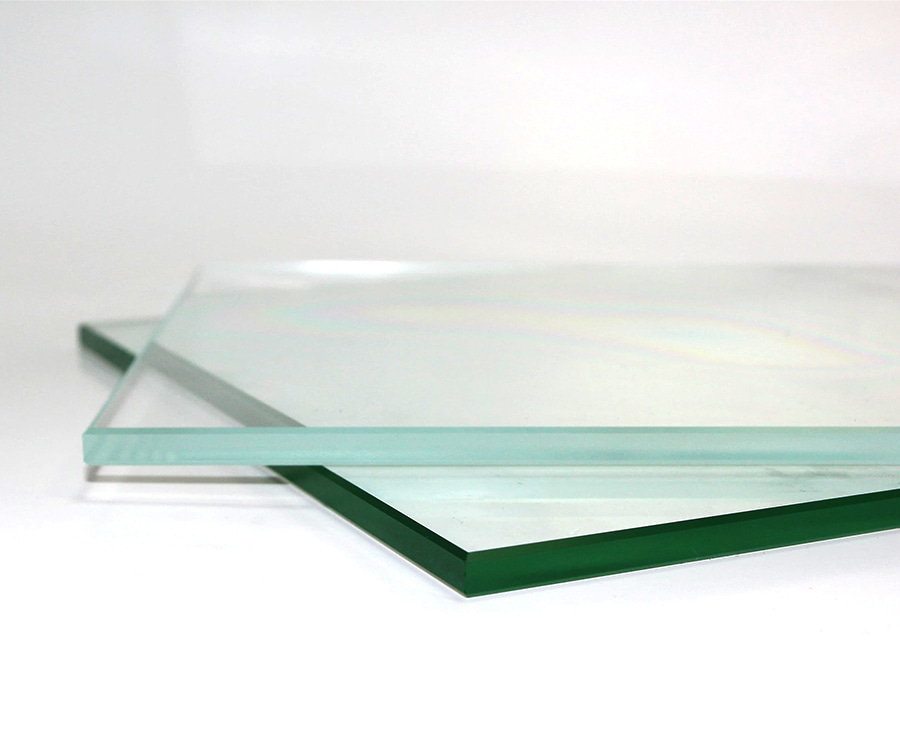

Tempered Glass: Whether used for the front or back panel of a module (for example, the PV module back panel glass you mentioned can be tempered or semi-tempered, available in 2.5mm and 2.0mm thicknesses), the tempering process provides it with extremely high mechanical strength and impact resistance, effectively withstanding severe weather conditions such as hail and high winds.

Chemical Stability: High-quality PV module glass requires excellent chemical resistance, particularly resistance to acid rain and salt spray.

Encapsulation Materials: The quality of the encapsulation film, such as EVA or POE, between the glass and the cell is also crucial. It prevents moisture intrusion and is crucial for protecting the cell and glass structure.

Manufacturing Process Precision

Advanced production processes, such as precise tempering and high-standard lamination techniques, ensure the sealing and internal structural stability of solar glass modules.

Application Environment and Maintenance

Extreme temperature and humidity fluctuations, as well as UV intensity at high altitudes, can affect module lifespan. Regular cleaning and inspection (especially of the PV glass surface) can maintain efficient module operation and extend its service life to a certain extent.

Technical Options for Extending the Life of PV Module Backsheet Glass

It is worth noting that in double-glass modules, the PV module backsheet glass replaces the traditional backsheet material. This configuration further enhances the module's weather resistance and water resistance.

Advantages of the Double-Glass Structure

The two layers of glass (front PV glass and rear PV module backsheet glass) provide superior moisture and heat barrier properties, better protecting the cells from environmental corrosion.

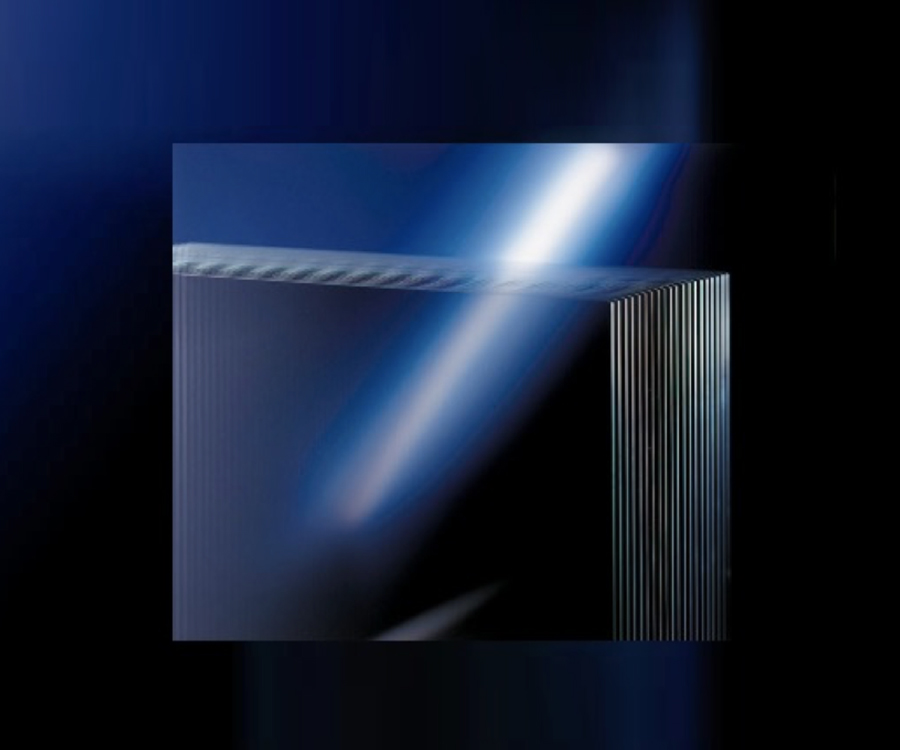

Special Treatment of Backsheet Glass

Some high-quality PV module backsheet glass uses an enameling process. For example, the enameled PV module backsheet glass you mentioned has a reflectivity of at least 75% within the 380-1100nm range. This not only helps improve module power generation efficiency but also further protects the internal structure, positively impacting the overall life of the solar module.

Thanks to the use of high-strength tempered glass, advanced sealing technology, and strict quality control, the design life of modern solar glass PV modules can easily meet or even exceed the industry standard of 25 years. With the continuous advancement of technology, such as the application of double-glass modules and enameled backplane glass, the long-term reliability of solar glass will continue to improve, providing more stable and long-term clean energy support for global sustainable development.