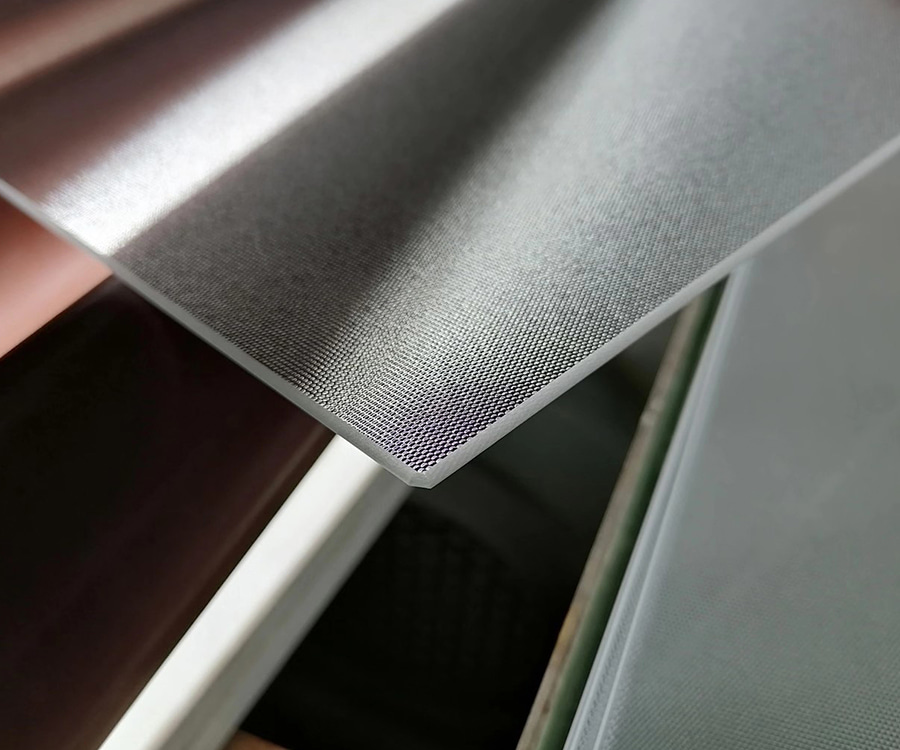

In the rooftop distributed power station scenario, the load-bearing structure often has certain limitations. If the weight of the photovoltaic module is too large, it may cause a large burden on the roof structure, and even affect its safety and service life. The 2.5mm thick Photovoltaic Module Backsheet Glass can effectively reduce the overall weight of the module while meeting the basic strength requirements of the photovoltaic module. This feature makes it an ideal choice for rooftop distributed power stations, reducing the stringent requirements for the rooftop load-bearing structure, while ensuring the safe and stable operation of the power station, it also reduces the construction cost and difficulty.

In addition, in general conventional installation environments, the 2.5mm thick Photovoltaic Module Backsheet Glass also performs well. It has sufficient mechanical strength to withstand various external force impacts in the daily environment, such as slight wind blowing, collision, etc.; at the same time, its good weather resistance enables it to adapt to different climatic conditions, whether it is direct sunlight, rain erosion or temperature changes, it can maintain stable performance, meet the needs of long-term stable operation of photovoltaic modules, and ensure power generation efficiency and system reliability.

The core goal of bifacial power generation modules is to improve power generation efficiency, and reducing the refraction loss of light on the back is a key link. The 2.0mm thick Photovoltaic Module Backsheet Glass adopts an ultra-thin design, and this unique advantage makes it play an important role in the light transmission process. When light shines on the back of the module, the ultra-thin glass can significantly reduce the reflection and refraction of light on the back, allowing more light to enter the cell smoothly, thereby improving the power generation performance of the bifacial power generation module and achieving higher energy conversion efficiency.

In some application scenarios that are extremely sensitive to weight, the advantages of 2.0mm thick Photovoltaic Module Backsheet Glass are more prominent. For example, for portable photovoltaic equipment, in order to facilitate carrying and use, the overall weight of the equipment needs to be reduced as much as possible; for lightweight rooftop photovoltaic systems, if the components are too heavy, it may cause damage to the roof or increase the difficulty of installation. At this time, the 2.0mm thick backplane glass can greatly reduce the overall weight of the component, improve the portability of the device, and allow users to move and use the device more easily. At the same time, it also increases the flexibility of installation and facilitates installation and adjustment in different locations.

However, in terms of climatic conditions, the scope of application of 2.0mm thick Photovoltaic Module Backsheet Glass is relatively limited. In areas with relatively mild climate conditions and low wind pressure, it can meet the use requirements. However, in areas with high wind pressure or extreme climate conditions, due to its relatively thin thickness, the impact resistance and weather resistance may be relatively weak. In these environments, it may be necessary to consider using thicker glass, such as 2.5mm or even thicker back glass, to improve the impact resistance and weather resistance of the module, and ensure that the photovoltaic module can still operate stably in harsh environments.