Home appliance display glass is a transparent material designed for home appliances, and is widely used in the appearance display and internal structure display of home appliances. Its main features include:

High light transmittance: ultra-white glass with high light transmittance can clearly display the appearance details of home appliances.

Strong customizability: supports CNC processing, can make special-shaped structures to meet the design requirements of different home appliances.

High safety: usually adopts thermal tempering or chemical tempering process, has excellent impact resistance, forms small particles when broken, and reduces safety hazards.

Outstanding aesthetics: personalized patterns and colors can be achieved through multi-color printing process to enhance the appearance design of home appliances.

Strong durability: smooth surface, not easy to scratch, and has good heat resistance and stain resistance, easy to clean and maintain.

Versatility: not only used to display the appearance of home appliances, but also can be used for transparent design of the internal structure of home appliances to enhance the overall display effect of the product.

Why is CNC processing used for home appliance display glass?

Home appliance display glass adopts CNC processing mainly because it can achieve high-precision and complex shape processing requirements, thus meeting the design requirements of modern home appliances for both aesthetics and functionality.

CNC processing is an automated processing technology controlled by a computer that can cut, engrave and shape glass materials with extremely high precision. In the manufacture of home appliance display glass, CNC processing can achieve the following advantages:

1. High precision and consistency

CNC machine tools can process with micron-level precision to ensure that the size and shape of each piece of glass fully meet the design requirements, while ensuring high consistency between batches. This is especially important for display screens in home appliances that require high visual effects and structural stability.

2. Realization of complex geometric shapes

With the diversification of home appliance product design, home appliance display glass is gradually tending to special-shaped structures. CNC processing can handle complex curved surfaces and polygonal structures, such as 3D glass shells, curved frames, etc., thereby enhancing the product's appearance design and technological sense.

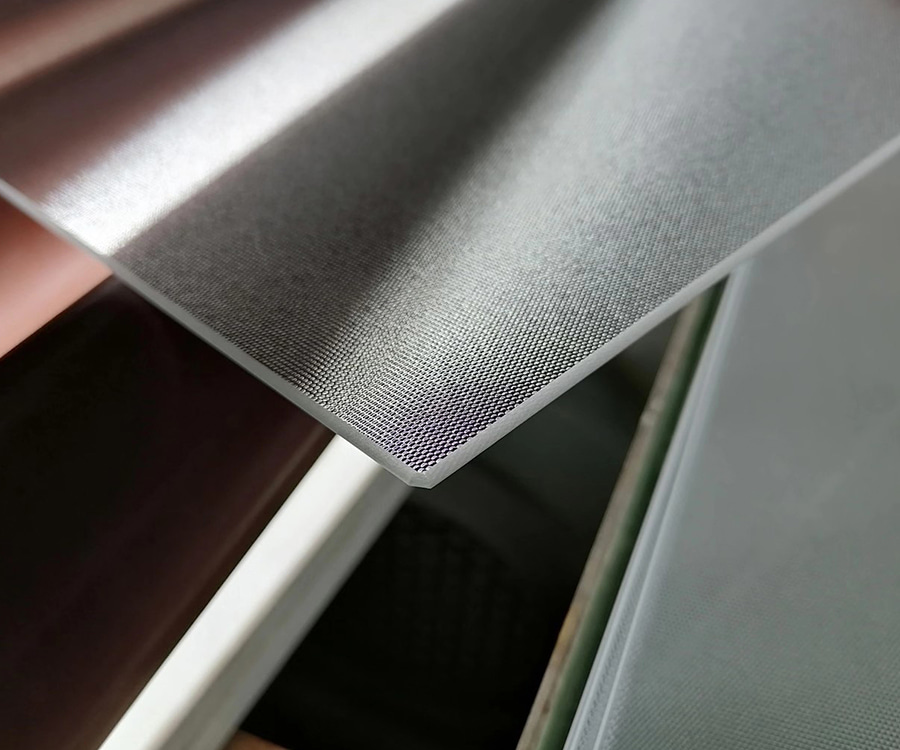

3. Surface quality and edge processing

CNC processing can not only achieve precise cutting, but also polish the edges of the glass during processing to ensure smooth and burr-free edges, thereby improving the overall aesthetics and durability. In addition, CNC processing can also be combined with processes such as acid etching to further enhance the edge strength of the glass, making it more suitable for practical use.

4. Efficient production and cost control

CNC processing is highly automated and repeatable, and can complete mass production in a short time, improve production efficiency and reduce costs. At the same time, due to the high processing accuracy, the need for subsequent trimming and rework is reduced, thereby further optimizing costs.

5. Compatible with a variety of materials and processes

CNC processing is not only suitable for glass, but can also be combined with processes such as chemical tempering and hot bending to further improve the impact resistance and optical quality of the glass. For example, through CNC processing combined with chemical tempering, home appliance display glass can have high light transmittance, high scratch resistance and good crack resistance.

What are the benefits of using thermal or chemical tempering for home appliance display glass?

Home appliance display glass plays a vital role in modern home appliance products. It is not only used to display the appearance of home appliances, but also undertakes structural support and decorative functions. In order to ensure its safety and durability during use, home appliance display glass is usually treated with heat tempering or chemical tempering process.

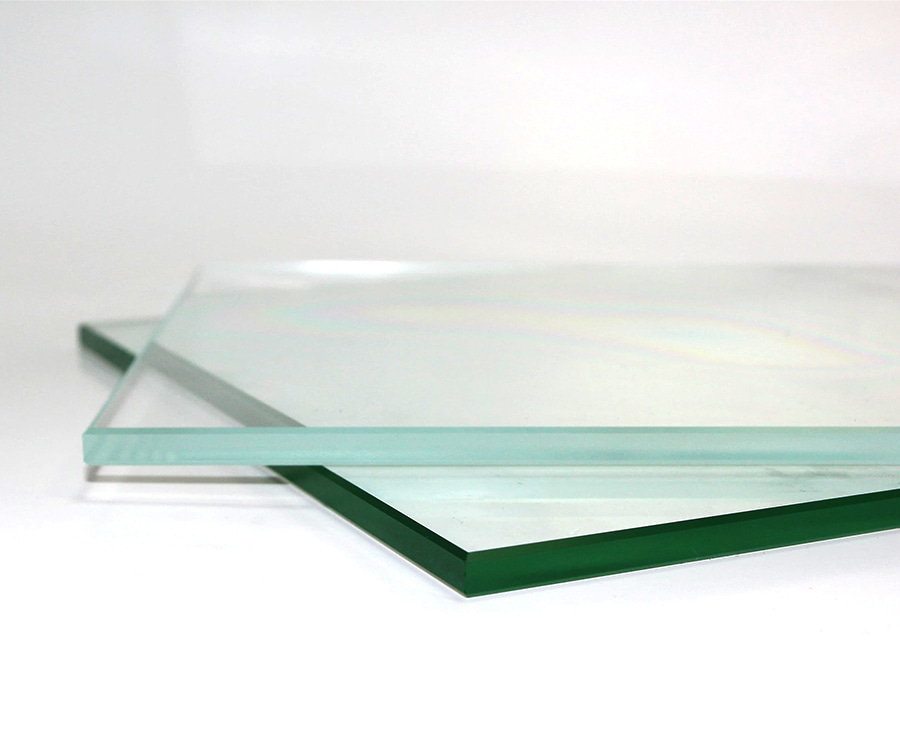

1. What is heat tempering?

Heat tempering is a process that generates compressive stress inside the glass by heating it to a temperature close to the softening temperature and then rapidly cooling (quenching). This compressive stress enables the glass to resist the expansion of cracks when subjected to external forces, thereby significantly improving its strength and safety.

2. Benefits of heat tempering for home appliance display glass

Significantly improve impact resistance

The impact resistance of heat tempered glass is 3 to 5 times that of ordinary glass, or even higher. In home appliances, especially large home appliances such as TVs, refrigerators, and air conditioners, display glass often needs to withstand a certain amount of physical impact. Heat tempered glass can effectively prevent glass breakage and ensure user safety.

Small particles are formed when broken

When heat tempered glass breaks, small particles similar to "honeycomb" are formed instead of sharp fragments. This characteristic greatly reduces the risk of harm to the human body, and is especially suitable for home appliances that children are more exposed to, such as display cabinets in children's rooms or children's toy display racks.

Good thermal stability

The thermal stability of heat-tempered glass is 2 to 3 times higher than that of ordinary glass, and it can withstand large temperature changes. For example, when home appliances are running at high temperatures, cracks may occur on the glass surface due to temperature differences, but the compressive stress structure of heat-tempered glass can effectively prevent this from happening.

Suitable for glass with complex shapes

The heat-tempered process can process glass of various shapes, including curved surfaces, special shapes, polygons, etc., which is very suitable for display glass with high requirements for shape in home appliances. For example, the frame of a TV, the door panel of a refrigerator, the exterior panel of an air conditioner, etc., can all be combined with beauty and safety through the heat-tempered process.

Enhance surface hardness

During the heat-tempered process, a compressive stress layer will form on the surface of the glass, which significantly increases the surface hardness, thereby enhancing its scratch resistance and anti-pollution ability and extending its service life.

3. What is chemical tempering?

Chemical tempering is a process of soaking glass in an alkaline solution to cause a chemical reaction on the surface of the glass to form a dense oxide layer, thereby improving the strength and hardness of the glass. Unlike thermal tempering, chemical tempering does not require high-temperature heating, so it is more suitable for fine processing of glass.

4. Benefits of chemical tempering for home appliance display glass

No need for high-temperature heating

The chemical tempering process is carried out at room temperature, avoiding the high-temperature quenching process required for thermal tempering, so it is more suitable for fine processing of glass, such as engraving, cutting, drilling and other operations.

Higher surface flatness

The surface flatness of chemically tempered glass is better than that of thermally tempered glass, and it is especially suitable for home appliance display glass with high optical performance requirements. For example, the backlight glass of the TV, the protective glass of the LED display, etc., all require extremely high surface flatness to ensure the display effect.

Suitable for thin glass processing

The chemical tempering process can process thinner glass, usually below 0.3mm, while thermally tempered glass has certain restrictions on the thickness of the glass due to the need for high-temperature quenching. Therefore, chemical tempering is more suitable for home appliances that have strict requirements on glass thickness.

Stronger scratch resistance

Chemically tempered glass has a higher surface hardness and better scratch resistance than thermally tempered glass, so it is more suitable for display glass, especially those parts that are frequently touched, such as touch screen protective glass or operation panel glass of home appliances.

Environmental protection and energy saving

The chemical tempering process does not require high-temperature heating, so the energy consumption is low and the impact on the environment is small, which is in line with the current trend of green manufacturing.

5. Summary: Comparison between thermal tempering and chemical tempering

| Item | Heat tempering | Chemical tempering |

| Processing method | High temperature heating + quenching | Chemical reaction at room temperature |

| Applicable thickness | Generally thicker | Suitable for thin glass |

| Surface flatness | General | Higher |

| Impact resistance | High | Medium |

| Scratch resistance | Medium | High |

| Applicable processing shape | Various | Complex |

| Advantages | High safety, strong impact resistance | No high temperature, environmentally friendly, suitable for thin glass |

| Disadvantages | Requires high temperature, high energy consumption | Slightly lower impact resistance |

6. Practical application in home appliance display glass

In home appliances, display glass usually needs to take into account safety, aesthetics and functionality. Therefore, thermal tempering and chemical tempering processes are often used in combination:

Thermal tempering + multi-color printing: used for the appearance display of large home appliances such as TVs and refrigerators, which not only ensures impact resistance, but also can achieve personalized design through multi-color printing.

Chemical tempering + CNC processing: used for home appliance display glass with high requirements for thickness and surface quality, such as transparent panels of products such as air conditioners and washing machines.

Heat-tempered + tempered glass edge treatment: used for frames, door panels and other structural parts of home appliances to ensure smooth edges and no burrs, thus improving the overall aesthetics.