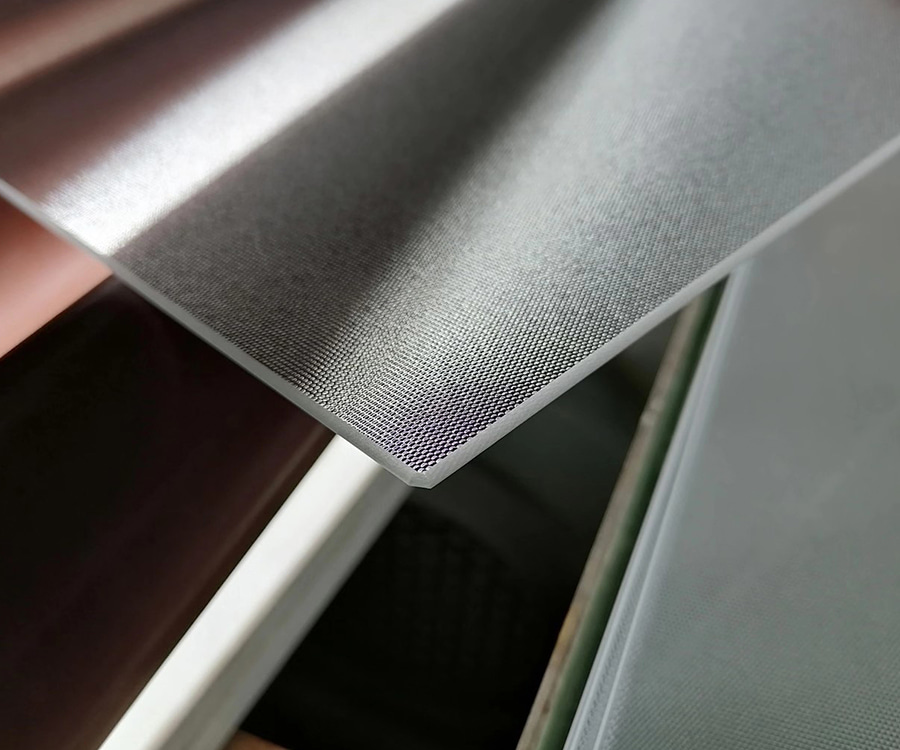

TCO solar glass, full name transparent conductive oxide (TCO) glass, is a high-tech product that uniformly coats a layer of transparent conductive oxide thin film on the surface of flat glass by physical or chemical coating methods. This material has become an indispensable key component in thin-film solar cells due to its excellent optical and electrical properties. With the rapid development of the photovoltaic industry, TCO glass is increasingly used in photovoltaic cells and has become an important force in promoting the progress of the photovoltaic industry.

Preparation and coating technology of TCO glass

The preparation and coating technology of TCO glass mainly includes two methods: online coating and offline coating. Online coating mainly adopts chemical vapor deposition process, and the coating process is directly placed in the cooling process of the float glass production line. The TCO raw material is transported to the top of the glass plate in gaseous form and diffused to the high-temperature glass surface. After adsorption, chemical decomposition reaction, and re-deposition, the film layer is synthesized. The advantage of this method is that the chemical composition and structure of the film layer are relatively stable, the diffusion layer is easy to form between the substrate and the film layer, and the film layer is firm and adaptable; at the same time, the coating process is integrated in the glass forming process, and the production efficiency is high.

Offline coating is to coat the glass separately after it leaves the factory, usually using magnetron sputtering technology in physical vapor deposition. The advantages of this method are that it is easy to control process parameters, the thickness and uniformity of the film layer can be accurately controlled, and it is highly flexible; the coating equipment is modularly designed, and the production capacity can be easily adjusted; the deposited layer is obtained under vacuum conditions, and the purity of the film layer is high. However, the disadvantages of offline coating are that the equipment is expensive, the process is complicated, the efficiency is low, and the overall manufacturing cost is high.

In the preparation process of TCO glass, different coating technologies correspond to different materials and processes. For example, FTO glass is mostly used for thin-film batteries, and the industrialization mainly adopts the online CVD method. The material price is lower than that of ITO, and it can be mass-produced with fast production speed. AZO glass has good light transmittance and conductivity, but it is difficult to mass produce at present, and there are still some problems in the process flow. Therefore, it has not become a mainstream process and is mainly made by PVD method.

Types and properties of TCO materials

TCO materials mainly include ITO (indium tin oxide), FTO (fluorine-doped tin oxide), AZO (aluminum-doped zinc oxide), etc. Among them, ITO coated glass has the characteristics of high transmittance, firm film layer and good conductivity, but its laser etching performance is poor, haze is low, and its price is high due to the rare element indium. FTO coated glass has become the mainstream product of thin-film photovoltaic cells due to its relatively low cost, easy laser etching and suitable optical performance. AZO glass is gradually becoming a new development direction due to its advantages such as easy availability of raw materials, low cost and non-toxicity.

What are the performance characteristics of TCO glass?

1. High transmittance

Definition: TCO glass has extremely high transmittance in the visible light range, usually with an average transmittance (T avg) of more than 80%, and some high-performance products can even reach more than 90%.

Function: High transmittance means that more sunlight can penetrate the glass and reach the absorption layer of the solar cell, thereby improving the power generation efficiency of the solar cell.

Influencing factors: Transmittance is affected by the coating material, film thickness, film uniformity and the optical properties of the glass substrate.

2. Anti-reflection function

Definition: TCO glass surface coating has good anti-reflection properties, which can reduce the reflection loss of sunlight on the glass surface and improve the light absorption efficiency.

Function: By optimizing the refractive index and thickness of the film layer, TCO glass can effectively reduce reflection, allowing more light to enter the battery layer, thereby improving the overall power generation efficiency.

Implementation method: The anti-reflection effect is usually achieved by designing the optical structure of the film layer (such as multilayer film, gradient film).

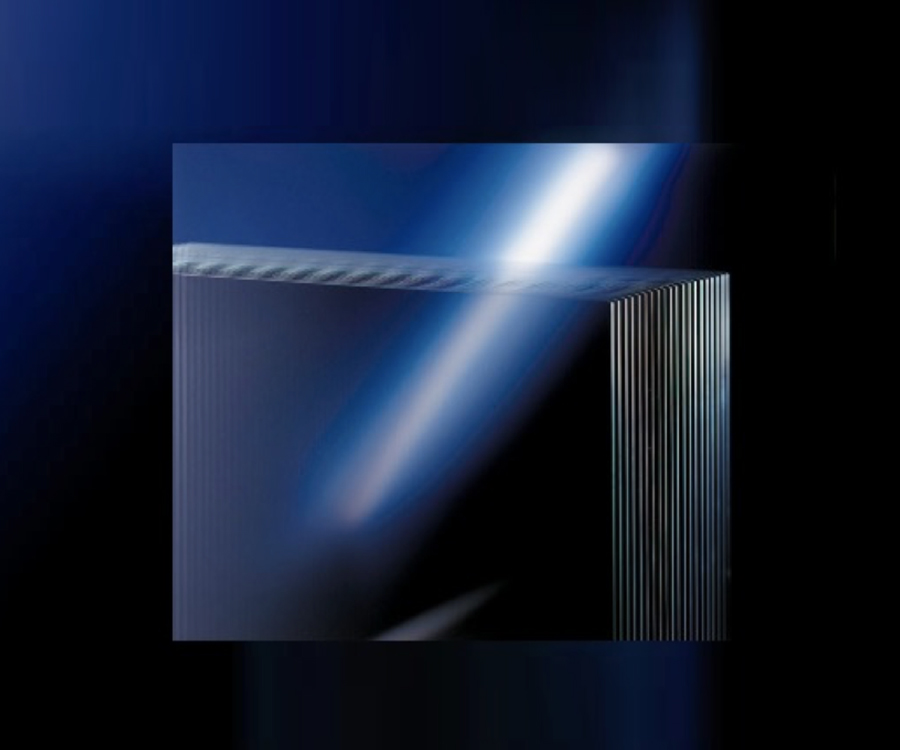

3. High conductivity

Definition: TCO glass has good conductivity while maintaining high transmittance, and its resistivity is usually less than 10⁻³ Ω·cm.

Function: As the front electrode of solar cells, TCO glass needs to provide a good conductive path to ensure that the current can be efficiently conducted from the battery layer.

Influencing factors: The conductivity is closely related to the material composition, thickness, crystallinity, doping concentration, etc. of the film layer.

4. Good mechanical properties

Hardness: The Mohs hardness of TCO glass is usually between 6.0 and 6.5, and it has high wear resistance and scratch resistance.

Strength: After tempering, the mechanical strength of TCO glass is significantly improved, and it can withstand certain external impact.

Thermal stability: TCO glass can still maintain good optical and electrical properties in high temperature environment, and is suitable for a variety of working environments.

5. Good chemical stability

Corrosion resistance: TCO glass shows good chemical stability in acid, alkali, moisture and other environments, and is not easy to corrode or oxidize.

Weather resistance: During long-term use, TCO glass can maintain the stability of its optical and electrical properties and is suitable for long-term outdoor use.

6. Adjustable square resistance and thickness

Square resistance: The square resistance of TCO glass can be adjusted according to specific needs, usually in the range of 10⁻³ ~ 10⁻⁴ Ω·cm².

Thickness control: By controlling the coating process parameters, the film thickness can be precisely controlled to meet the needs of different application scenarios.

7. Good machinability

Cutting and etching: TCO glass has good machinability, is easy to cut, drill and laser etch, and is suitable for large-scale production.

Compatibility: TCO glass has good compatibility with a variety of packaging materials (such as EVA, glass glue), which is easy to integrate into photovoltaic modules.

8. Environmental protection and sustainability

Material environmental protection: Some TCO materials (such as AZO) are non-toxic and non-polluting, which is in line with the trend of green manufacturing.

Recyclability: After the service life of TCO glass, both its film layer and glass substrate can be recycled to reduce resource waste.

Application areas of TCO glass

1. Photovoltaic field

TCO glass is one of the core materials of thin-film solar cells (such as amorphous silicon, cadmium telluride, perovskite, etc.). As the front electrode of the battery, it is responsible for collecting and transmitting photocurrent. Its high transmittance and low resistivity make it a key component to improve the efficiency of solar cells.

2. Building energy saving

TCO glass can be used for energy-saving glass in buildings, such as low-emissivity (Low-E) glass and smart color-changing glass. It can effectively reduce the heat loss of solar radiation and improve the energy efficiency of buildings while maintaining good lighting performance.

3. Flat panel display

In the field of flat panel displays, TCO glass (especially ITO glass) is widely used in electrodes of liquid crystal displays (LCDs) and electroluminescent displays (ELDs). Its high conductivity and transparency make it an important material for display devices.

4. Smart glass

TCO glass can be used for smart color-changing glass and electromagnetic shielding glass. By adjusting the optical properties of the film layer, smart glass can automatically adjust transparency under different lighting conditions to achieve energy saving and privacy protection functions.

5. Heat-insulating energy-saving windows

TCO glass plays an important role in heat-insulating energy-saving windows. It can effectively reduce the temperature difference between the inside and outside of the building, reduce air conditioning energy consumption, and improve the comfort and energy efficiency of the building.

6. Heated anti-fog glass

TCO glass can be used for heated anti-fog glass. By applying voltage on the glass surface, the glass surface can be quickly heated and anti-fog functions can be achieved. It is widely used in automobiles, ships, buildings and other fields.

7. Electromagnetic shielding windows

TCO glass has good electromagnetic shielding performance and can be used for electromagnetic shielding windows to prevent the influence of electromagnetic interference on electronic equipment. It is suitable for highly sensitive fields such as communication equipment and medical equipment.

8. Gas sensors

TCO glass can also be used as gas sensors in some special applications to detect gas concentrations, such as in environmental monitoring and industrial safety.

9. Touch screens

TCO glass is widely used in touch screen technology, such as touch panels for smartphones, tablets and laptops, due to its high transparency and conductivity.

10. OLED lighting

TCO glass also has important applications in OLED lighting, and its high transparency and low resistance make it an ideal conductive material for OLED devices.

11. Transparent electronics

TCO glass is also widely used in transparent electronics, such as transparent displays, solar cells and touch panels, meeting the dual needs of transparency and conductivity of modern electronic devices.

12. Automotive displays

TCO glass is also important in automotive displays, such as rearview mirrors, dashboards and head-up displays. With the popularization of electric vehicles, its market demand will further increase.

With the rapid development of the photovoltaic industry, the market demand for TCO glass has grown rapidly, becoming a hot high-tech coated glass product. It is expected that the global TCO glass market will continue to grow in the next few years, especially in the fields of thin-film solar cells and building energy conservation.

As a key material in the photovoltaic industry, the performance and application prospects of TCO glass have attracted much attention. With the continuous advancement of technology and the growth of market demand, TCO glass will play an important role in more high-tech fields and inject new vitality into the development of the photovoltaic industry.