The fundamental difference between solar photovoltaic glass and ordinary glass lies in their functional attributes and technical structures. Ordinary glass is mainly used for lighting, protection, and decoration, while solar photovoltaic glass not only has basic glass properties but also undertakes multiple functions such as light transmission and power generation, module encapsulation, protection, and structural support. It is one of the core materials in photovoltaic power generation systems. It belongs to functional industrial glass, not ordinary architectural glass.

Content

Functional positioning difference: power-generation material vs. building material

Core functions of solar photovoltaic glass serving photovoltaic systems: high transmittance to ensure solar energy absorption, serving as a carrier for solar cell encapsulation, participation in the photoelectric conversion system, structural support function of modules, long-term outdoor operation capability

Main functions of ordinary glass: lighting, partitioning, protection, decoration, building envelope structures

Essential difference: solar photovoltaic glass is a “functional energy material,” while ordinary glass is a “structural building material.”

Differences in material composition and manufacturing processes

Material characteristics of solar photovoltaic glass: low-iron ultra-clear glass substrate, iron content ≤ 0.02% (ordinary glass about 0.1%), high-purity quartz sand raw materials, low impurity content, high light transmittance

Raw material structure of ordinary glass: ordinary quartz sand, higher iron content, relatively lower light transmittance, lower impurity control standards

Key difference: light transmittance performance and impurity control standards

| Type | Visible light transmittance |

| Solar photovoltaic glass | ≥ 91.5% |

| Ordinary architectural glass | 80%–85% |

Light transmittance performance comparison

Data significance: for every 1% increase in transmittance, photovoltaic module power generation efficiency can increase by about 0.5%–0.8%, which has a significant impact on the long-term returns of power generation systems.

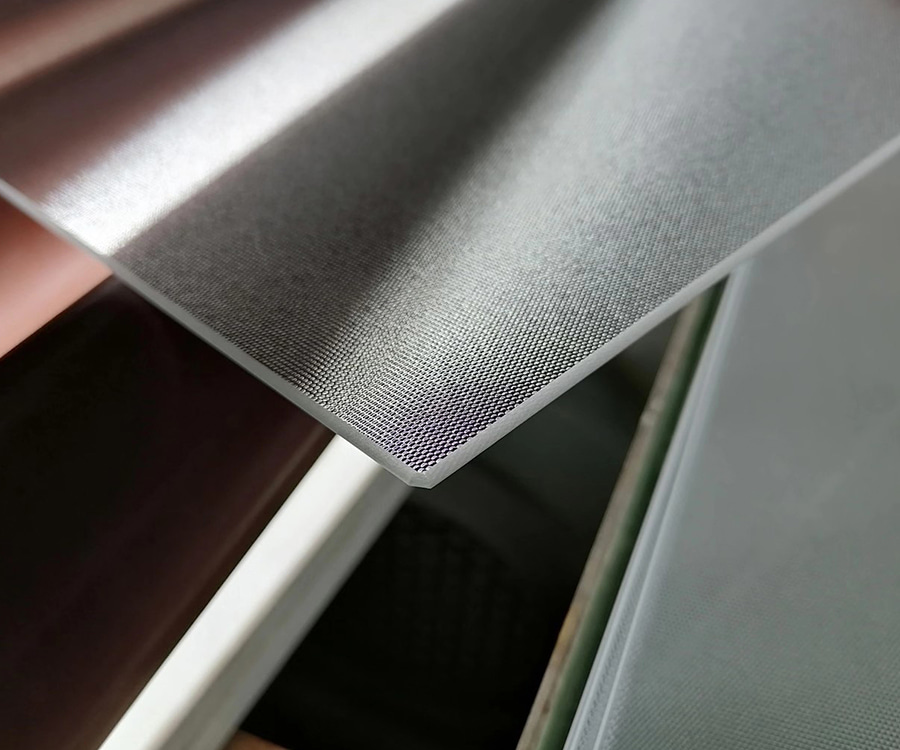

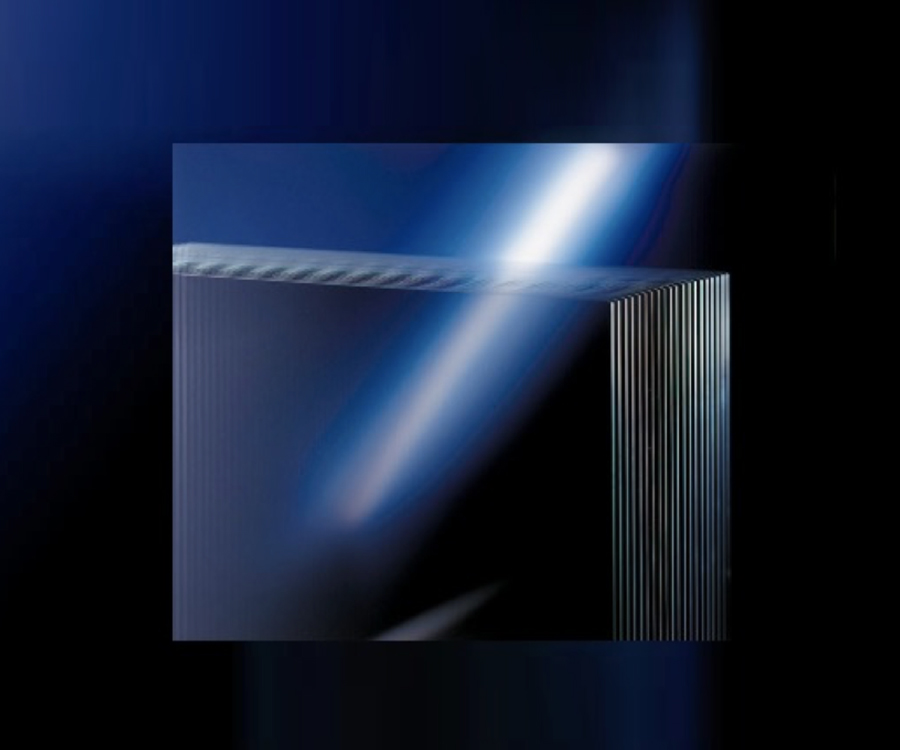

Solar photovoltaic glass usually has: rolled texture structures, matte anti-reflection design, AR anti-reflection coating, anti-glare treatment, anti-fouling self-cleaning coating (some models)

Surface structure of ordinary glass: mainly smooth surfaces, no functional coatings, no optical optimization design. Optical engineering structures are important technical barriers of solar photovoltaic glass.

Solar photovoltaic glass usually adopts: tempering processes, wind pressure resistance, hail impact resistance, thermal shock resistance, mechanical load resistance, UV aging resistance

Ordinary glass: mainly ordinary annealed glass, weak impact resistance, poor thermal stability, average outdoor weather resistance

Solar photovoltaic glass design life: ≥ 25-year system life, high-temperature resistance, cold resistance, stable in high-humidity environments, stable in strong ultraviolet environments

Ordinary glass: easy aging in long-term outdoor use, prone to surface degradation, limited weather resistance, not suitable for energy system applications

Application scenarios

Solar photovoltaic glass: photovoltaic module encapsulation, photovoltaic power stations, BIPV (building-integrated photovoltaics), distributed photovoltaic systems, industrial and commercial rooftop photovoltaics, photovoltaic carports, agrivoltaic systems

Typical applications of ordinary glass: building doors and windows, curtain walls, indoor partitions, home decoration, display windows, ordinary envelope structures

Solar photovoltaic glass: complex production processes, high technical barriers, strict quality control, high functional added value, belonging to the energy materials industry chain

Ordinary glass: mature processes, low cost, low technical barriers, belonging to basic building materials

Core difference summary

Solar photovoltaic glass is not “better ordinary glass,” but a “professional material with a completely different functional positioning.”

| Dimension | Solar photovoltaic glass | Ordinary glass |

| Function | Core material of power generation systems | Building lighting material |

| Transmittance | High | Photovoltaic industry |

| Strength | High | Low |

| Weather resistance | Extremely strong | Average |

| Service life | Over 25 years | Relatively short |

| Technical content | High | Low |

| Application field | Photovoltaic industry | Architectural decoration |

With the development of the new energy industry, solar photovoltaic glass has been upgraded from a “material product” to a “key component of energy systems.” It not only undertakes the light-transmission function, but also participates in the construction of power generation efficiency, safety, and stability of the entire photovoltaic system. Ordinary glass remains an important basic material in the construction field, but the two have completely diverged in technical paths, industrial positioning, and functional goals. In actual engineering selection, solar photovoltaic glass cannot be replaced by ordinary glass, otherwise it will directly affect power generation efficiency, system life, and safety level. This is a basic technical consensus in photovoltaic system design.