Solar glass is primarily made of ultra-clear patterned glass, with core raw materials including quartz sand, soda ash, limestone, dolomite, and sodium sulfate. Unlike ordinary architectural glass, solar glass must have extremely high light transmittance to improve the conversion efficiency of photovoltaic cells. By reducing the iron content in the raw materials (usually below 150 ppm), solar glass can reduce the absorption of sunlight, allowing more energy to penetrate the glass and reach the underlying photovoltaic components.

Content

Core Components and Structure of Solar Glass

Solar glass is not only a protective shield for photovoltaic components but also a key element in improving power generation efficiency. The following are its main components and manufacturing process:

1. Basic Raw Materials

Low-iron quartz sand: This is the most critical raw material. Ordinary glass appears green because it contains iron impurities, while solar glass uses high-purity low-iron sand, making it almost completely transparent.

Fluxes and stabilizers: Soda ash is used to lower the melting point of silica sand, while limestone enhances the chemical stability and physical strength of the glass.

2. Special Optical Structure

To maximize the utilization of solar energy, solar glass usually adopts the following designs:

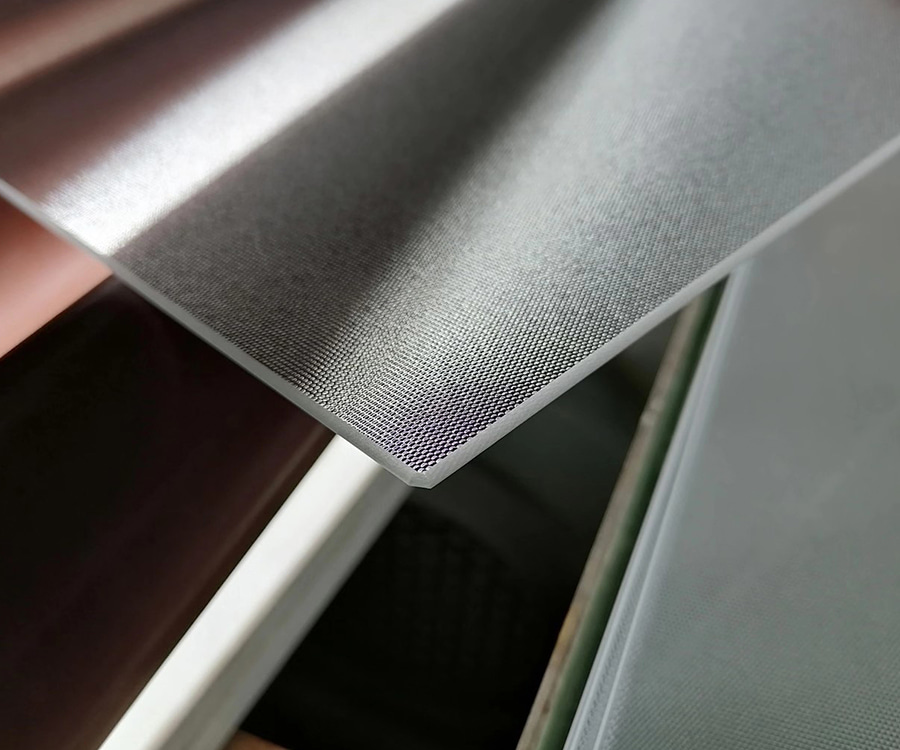

Embossing treatment (textured surface): A specific pyramid-shaped or textured pattern is pressed onto the glass surface, which reduces specular reflection and causes incident light to diffuse, increasing the path length of light on the solar cells.

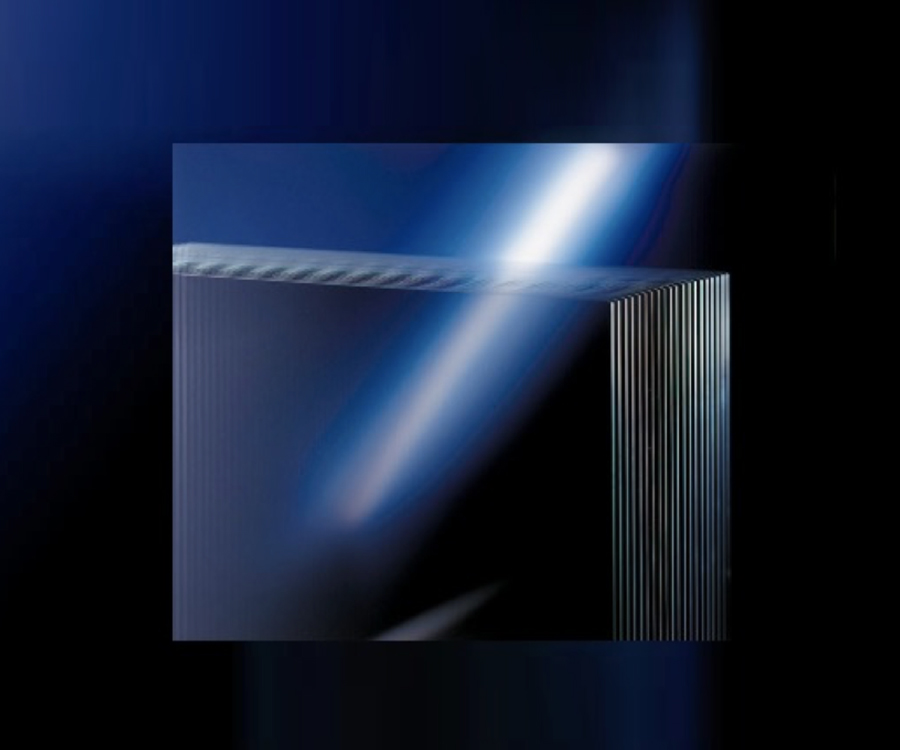

Anti-reflective coating (AR Coating): A nanometer-thick silicon dioxide coating is applied to the glass surface, increasing light transmittance from approximately 91% to over 94%.

Mainstream Technology Types of Solar Glass

Ultra-clear patterned glass (mainly used for crystalline silicon cells): This is currently the most widely used type of solar glass in the photovoltaic industry. Through a special embossing process, a specific texture (such as a textured or pyramid shape) is formed on the glass surface. This structure effectively reduces specular reflection and increases diffuse reflection of light, thereby improving photoelectric conversion efficiency. In addition, tempered patterned glass has extremely high physical strength and is the preferred protective material for distributed photovoltaic power plants and ground-mounted power plants.

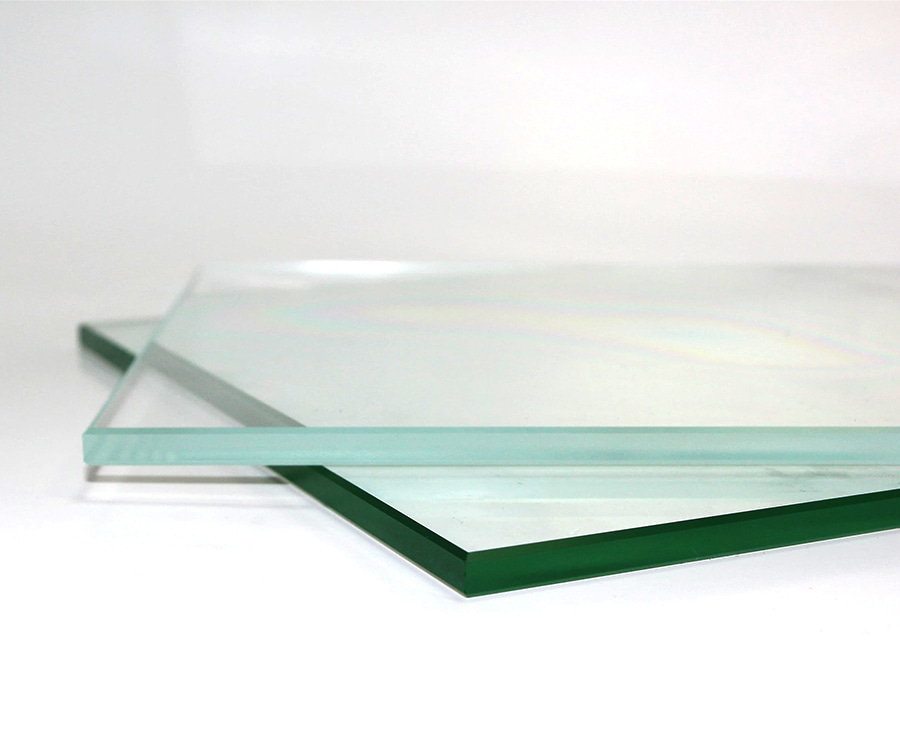

Ultra-clear float glass (mainly used for thin-film cells): Unlike patterned glass, ultra-clear float glass has an extremely flat and smooth surface. Due to its manufacturing process that guarantees extremely high flatness, it is commonly used as a substrate for thin-film solar cells.

In thin-film cells, the semiconductor layer needs to be deposited directly onto the glass surface, thus requiring almost stringent demands on the flatness and transparency of the glass surface. Ultra-clear float glass perfectly meets this precision manufacturing requirement.

Why is Solar Glass Crucial in the Photovoltaic Industry?

With the acceleration of the global energy transition, the demand for solar glass continues to rise. It not only needs to possess extremely high impact resistance (to withstand hail and sandstorms) but also excellent weather resistance to ensure that photovoltaic modules have a service life of over 25 years in harsh outdoor environments.

Furthermore, the popularization of double-glass modules (double-sided solar glass) has further driven technological advancements. This structure not only enhances the mechanical strength of the module but also utilizes reflected light from the back to generate electricity, significantly increasing the total power generation.

Understanding "what solar glass is made of" is fundamental to understanding photovoltaic power generation efficiency. From the selection of high-purity raw materials to advanced anti-reflective coating processes, every technological advancement is contributing to making green energy more affordable.