The glass surface determines 90% of a user's visual and tactile experience with a conference machine. Specifically, high-quality chemically etched Anti-Glare (AG) glass eliminates room reflections that cause eye strain, ensures smooth touch sensitivity for writing, and protects the expensive LCD panel from physical damage. Without specialized glass, a high-resolution 4K display becomes unusable in brightly lit offices due to "mirror effects" and fingerprint smudges.

Content

What exactly is "Conference Equipment Glass"?

Conference Device Glass is a specialized cover lens—usually 3mm or 4mm tempered glass—that has undergone chemical or physical surface treatments to optimize it for indoor group viewing. Unlike standard window glass, it is engineered for optical clarity and touch performance.

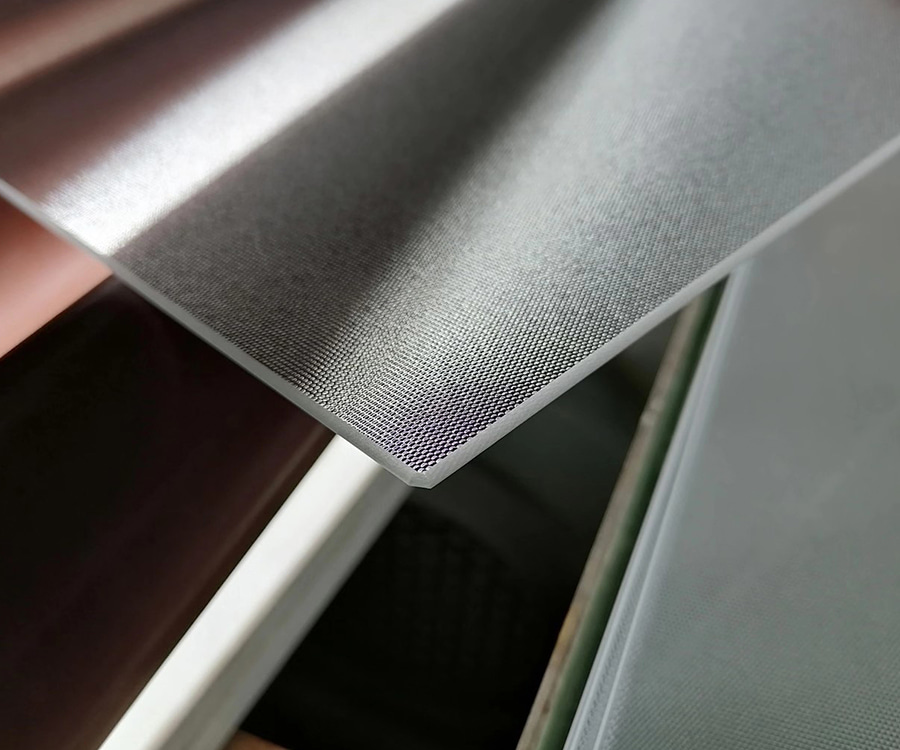

Chemical Etching (AG): This involves dipping the glass into an acid bath to create a microscopic "frosted" texture. This texture diffuses incoming light, reducing glare.

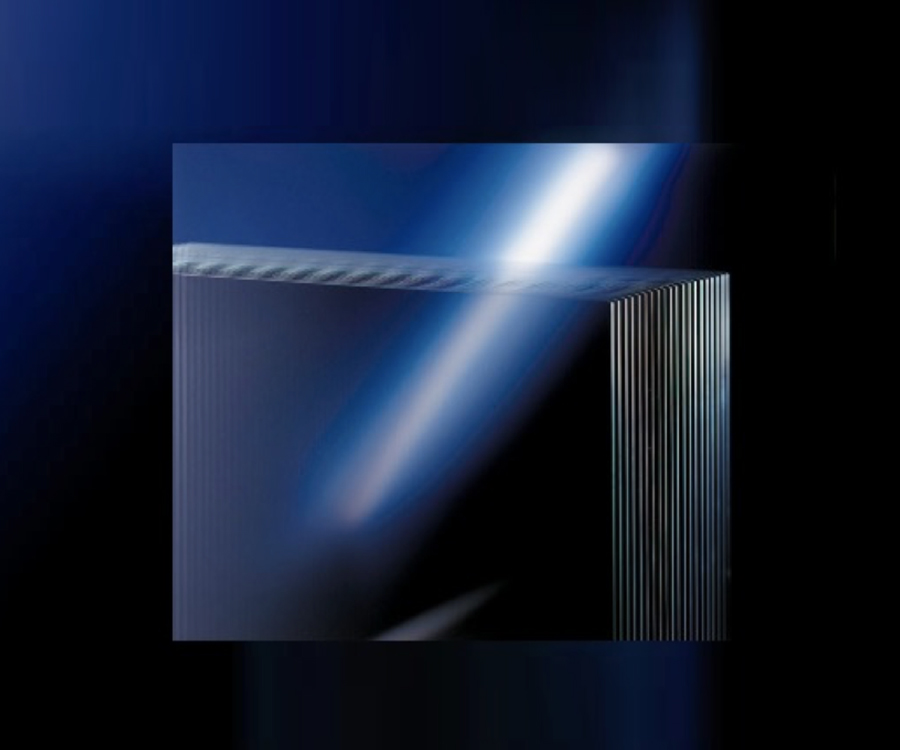

Vacuum Coating (AR/AF): Layers of metal oxides are applied in a vacuum chamber to increase light transmission (Anti-Reflective) or repel skin oils (Anti-Fingerprint).

Why is selecting the right glass important for your ROI?

Choosing the wrong glass leads to "Project Failure" after installation. According to a study on office ergonomics by the Cornell University Ergonomics Abstract, glare on computer screens is a leading cause of visual discomfort and decreased productivity.

Legibility from All Angles: In a 20-person boardroom, people sitting at the sides often see reflections instead of content. Etched AG glass provides a viewing angle of up to 178 degrees without significant contrast loss.

Writing Latency and Friction: Professional Conference Device Glass is tested for a "Coefficient of Friction" (CoF). High-quality etched glass mimics the feel of pen-on-paper, whereas untreated glass feels sticky or "stuttery" to the user.

Durability Standards: Quality Conference Device Glass must meet the IK08 or IK09 impact rating (as defined by the IEC 62262 international standard), ensuring it can withstand a heavy accidental blow without shattering.

How does Anti-Glare (AG) glass work to stop reflections?

It works through Diffuse Reflection. When light hits a smooth surface (like a mirror), it bounces back at the same angle, hitting your eyes as a "glare." The chemical etching process creates a surface roughness (measured in "Gloss" units).

When light hits this textured surface, it scatters in millions of different directions. This turns a sharp, blinding reflection of a window into a soft, unnoticeable glow. For most conference rooms, a Gloss level of 70 to 95 is the "sweet spot" that balances glare reduction with image sharpness.

What should I look for when inspecting a glass supplier?

To avoid "empty" marketing claims, ask your manufacturer for specific data points and certifications:

Ask for the Gloss Meter Reading: Ensure they can provide a consistent Gloss range.

Verify the Mohs Hardness: Conference Device Glass should typically be 7H or higher to resist scratches from rings or styluses.

Check for "Haze" Percentage: Haze should generally be kept between 3% and 8% for conference displays; anything higher will make your 4K screen look like a 1080p screen.

Edge Treatment: Ensure the glass uses C-shape or R-shape diamond polishing. Rough edges lead to "stress fractures" where the glass can spontaneously crack after installation.