In today's digital age, Touchscreen Panel Glass has become an indispensable part of our daily lives. From smartphones and tablets to car dashboards and industrial control equipment, high-quality touchscreen panel glass not only enhances the visual appeal of products but also directly impacts the smoothness of user interaction.

So, how can we efficiently and scientifically use and customize Touchscreen Panel Glass in different application scenarios? This article will provide an in-depth analysis.

Content

1. Customizing the Form Based on Structural Needs

Modern electronic product design pursues personalization and differentiation. High-quality Touchscreen Panel Glass is no longer limited to the traditional rectangular shape.

Irregular Shape Processing: Depending on the requirements of the device casing, touchscreen panel glass can be customized into irregular shapes, perfectly fitting wearable devices or automotive displays.

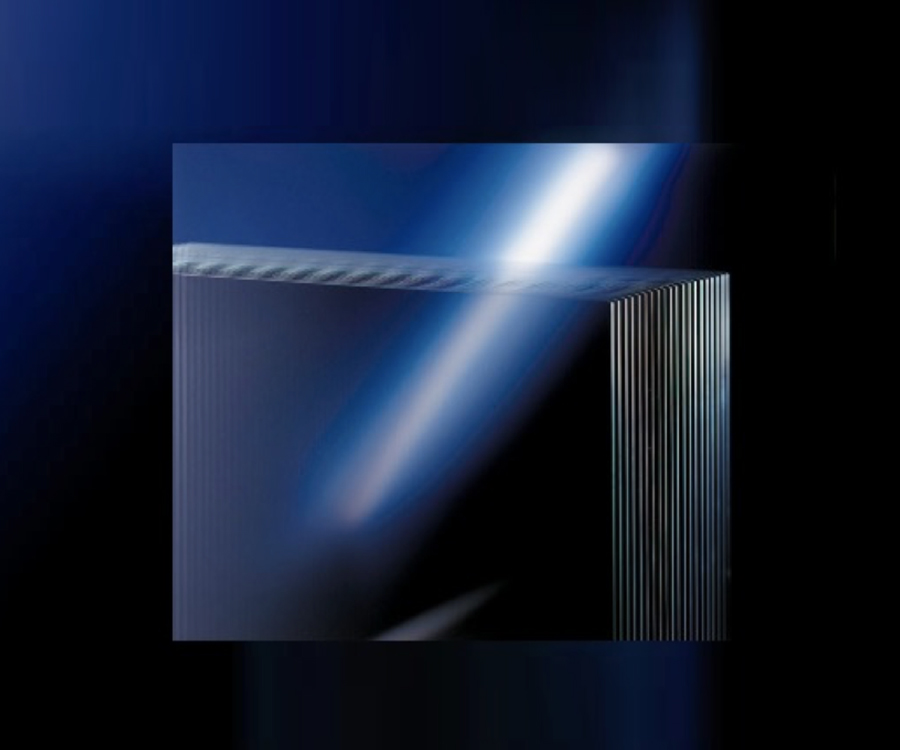

Precision Processing: Through high-precision cutting and forming technology, perforations or other complex external structural features can be added to the glass to accommodate camera, button, or speaker locations.

2. Surface Treatment Selection Based on Environment

Touchscreen Panel Glass is used in a variety of environments, therefore, specific processing methods are necessary to optimize its performance:

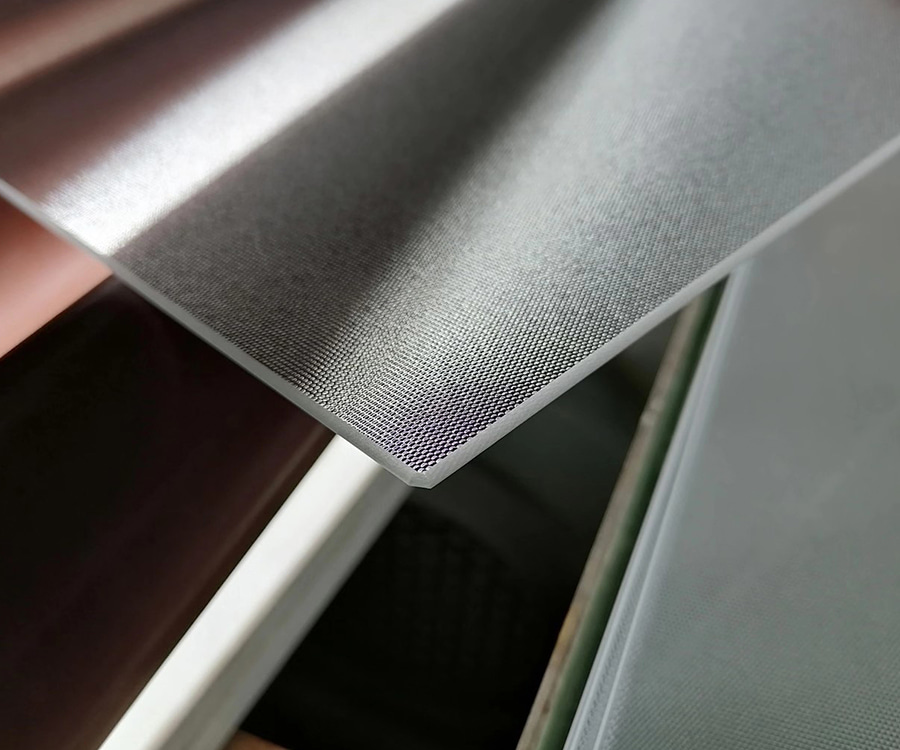

Optical Performance Optimization: If the device is used in strong light, AG (anti-glare) or AR (anti-reflective) treatments can be applied. After electroplating to improve transparency, the visible light transmittance of the glass can be increased from 91% to over 94%, ensuring a clear and transparent screen.

Enhanced Durability: Through chemical hardening (chemical strengthening) processes, the impact resistance and hardness of the glass are significantly improved.

Enhanced User Experience: Adding an AF (anti-fingerprint) coating effectively reduces fingerprint residue, maintaining the cleanliness and silky smooth feel of the touchscreen panel glass.

3. Fusion of Color and Aesthetics

Touchscreen Panel Glass is not only a functional component but also part of the overall design.

Diverse Printing: Utilizing advanced printing processes, various patterns and color effects can be printed on the edges or surface of the glass, achieving perfect consistency with product logos, decorative textures, or UI interfaces.

Core Technological Advantages of Touchscreen Panel Glass

Ultra-High Transparency: Basic visible light transmittance exceeds 91%; after electroplating anti-reflective treatment, transmittance can exceed 94%, ensuring exceptionally clear images.

Comprehensive Shape Customization: Supports irregular shape customization and precision perforation; thanks to high-precision cutting and forming processes, it perfectly adapts to various complex external structures.

Diverse Surface Treatments: Covers chemical hardening reinforcement, anti-glare (AG), anti-reflective (AR), and anti-fingerprint (AF) coatings, comprehensively improving durability and feel.

Superior Visual Aesthetics: Supports printing various colors and patterns on Touchscreen Panel Glass, achieving a high degree of unity between functionality and decoration.

Choosing and using good Touchscreen Panel Glass is key to balancing its optical performance, structural strength, and aesthetic appeal according to the actual application scenario of the product. With high-precision processing technology and a wealth of surface treatment technologies, customized touchscreen panel glass is providing a superior interactive experience for smart terminals worldwide.