In modern architectural design and interior decoration, Screen-printed glass has become a mainstream material that combines aesthetic value with functionality. Whether it's the vibrant facades of skyscrapers or minimalist home partitions, screen-printed glass plays a crucial role.

Content

What is Screen-Printed Glass?

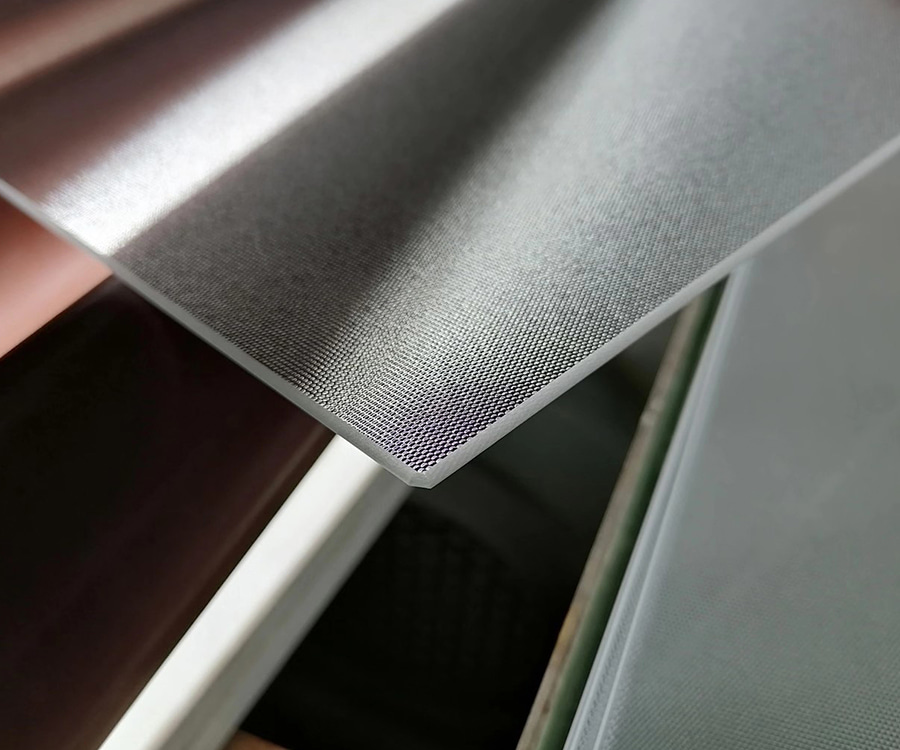

Screen-printed glass is a decorative glass material made by printing inorganic pigments (also known as inks) onto the glass surface using a special screen. The designs or text are then dried, tempered, or heat-strengthened to permanently fuse the pigments to the glass surface.

This process not only gives the glass a rich variety of colors and patterns but also provides excellent wear resistance, acid and alkali resistance, and fade resistance.

The Production Process of Screen-Printed Glass

Understanding the production process of screen-printed glass helps us better understand the source of its quality:

Design and Screen Making

Vector graphics are designed according to customer requirements and then made into photosensitive screens.

Screen Printing

The prepared high-temperature glaze is placed on a screen, and the glaze is transferred through the mesh to a clean glass surface using squeegee pressure.

Drying Treatment

The printed glass enters a drying tunnel to allow the glaze to initially solidify, preventing pattern distortion.

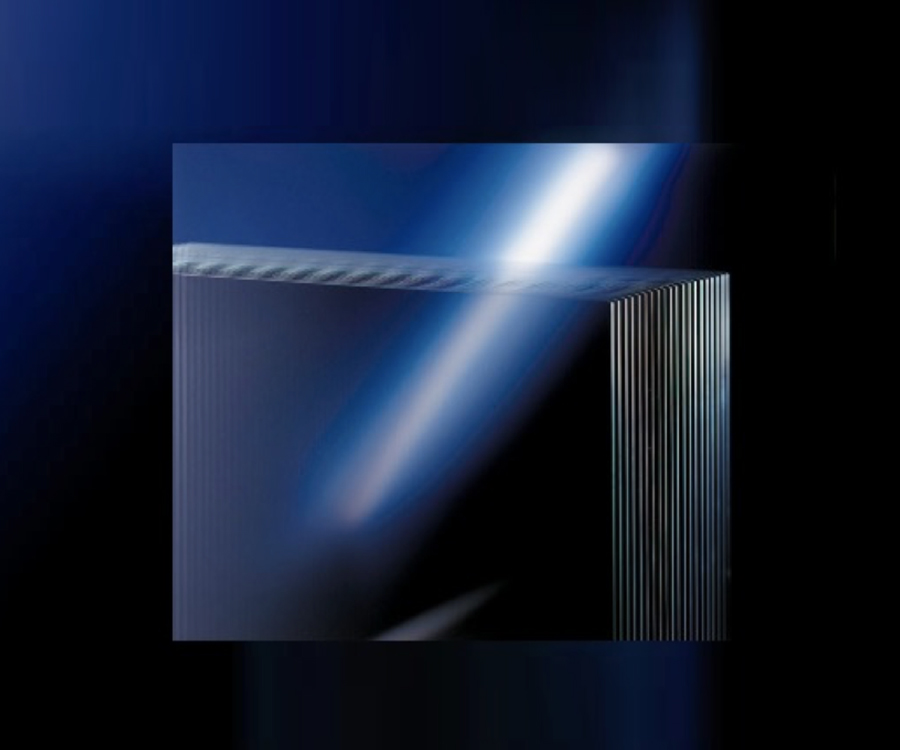

High-Temperature Sintering (Tempering)

This is the most crucial step. The glass enters a tempering furnace, where the glaze fuses with the glass surface at a high temperature of 600°C to 700°C, forming a strong colored glaze layer.

Key Advantages of Screen-Printed Glass

Why do designers and homeowners favor screen-printed glass among numerous glass processing products?

1. Superior Decorative Value

From simple lines and dot matrices (such as anti-slip dots) to complex geometric patterns, screen-printed glass perfectly reproduces design intent. It can simulate stone, wood, or other textures, achieving extremely high visual expressiveness.

2. Functional Control: Sunshade and Privacy

By printing dot matrices or patterns of varying densities, light transmittance can be effectively controlled, providing sunshade and privacy protection.

3. Anti-slip Performance

In glass flooring or staircase applications, special anti-slip enamel printing significantly improves safety.

4. Long-lasting and Fade-resistant

Due to the high-temperature sintering process, the enamel exhibits extremely stable physical and chemical properties. Even with prolonged exposure to strong UV rays or harsh weather conditions, screen-printed glass maintains its vibrant color without peeling or fading.

5. High Strength and Safety

Because screen printing is often combined with tempered glass processing, the finished product possesses extremely high mechanical strength and thermal stability. Even if broken, it will shatter into small, blunt-angled particles, reducing the risk of injury.

Common Applications

Due to its versatility, screen-printed glass is widely used in various engineering fields:

Building Exteriors: Used for curtain wall glass, sunshade louvers, and window frames, enhancing the visual appeal of building facades.

Interior Decoration: Glass partitions, feature walls, shower rooms, glass doors.

Furniture Accessories: Glass tabletops, cabinet panels, electronic product panels.

Transportation Facilities: Decorative glass for bus shelters, subway platform screen doors, etc.

Screen-printed glass is a perfect fusion of art and industrial technology. It not only offers architecture a rich selection of colors and textures but also enhances the comfort and safety of spaces through functional design. In today's pursuit of personalization and quality, screen-printed glass is undoubtedly a leader among decorative materials.